Drum Peeler is suitable for various root-based materials such as cassava, potatoes, carrots, radishes etc.

Drum Peeler Assists Value-Add @

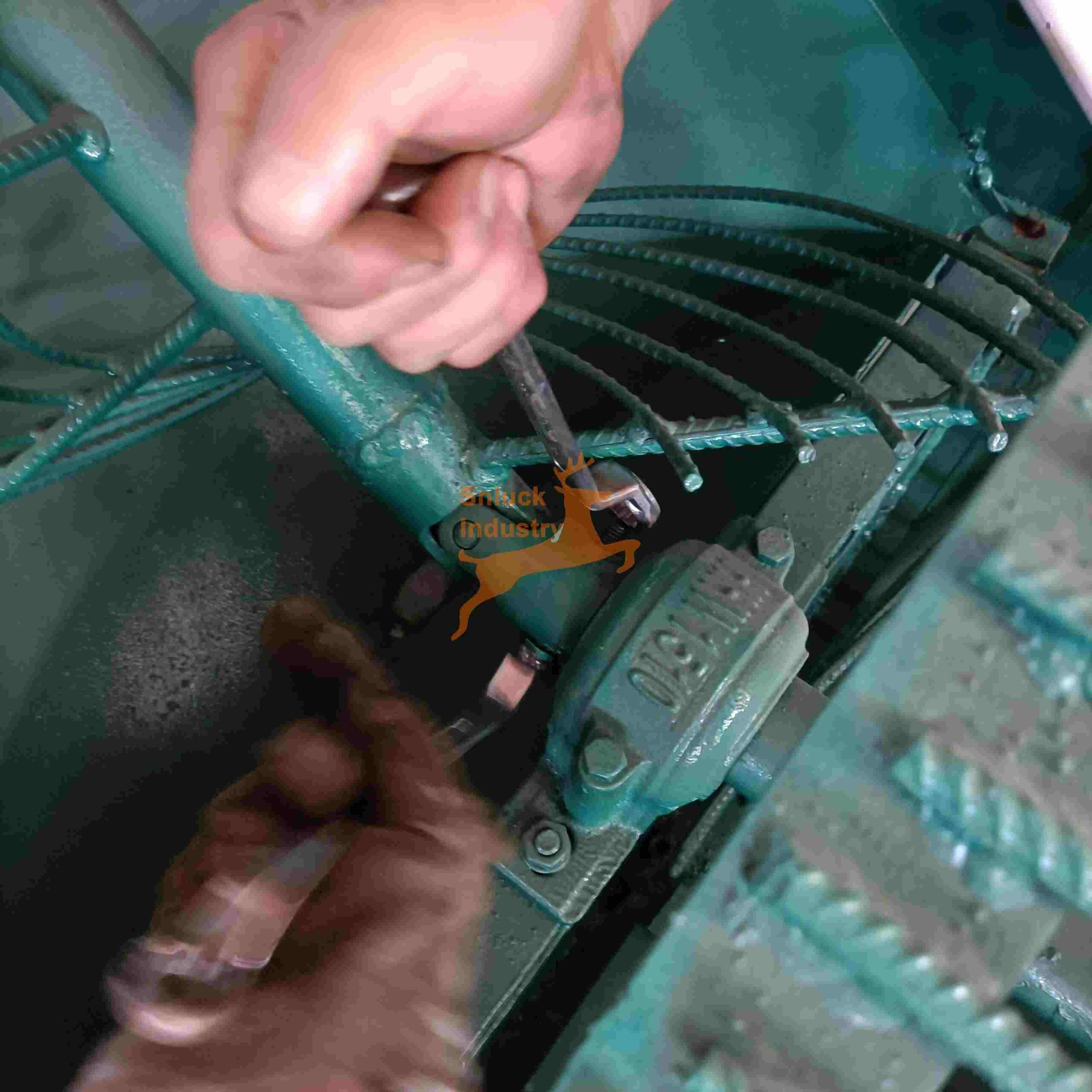

Components of Drum Peeler -

Structure Parts

Principle for Better –

Function

Easy Use of Drum Peeler -

Instruction

- 1

Plug & Play, ensure the drum peeler is properly installed and connected to the power supply.

- 2Button-push to Load the root-based materials into the drum.

- 3Button-push to Start the machine and adjust the rotation speed and water flow as needed.

- 4Monitor cleaning effect and make necessary adjustments.

- 5

Button-push to turn off the machine and remove the cleaned materials.