Batch Dryer Achieves Well-dry @

- 1

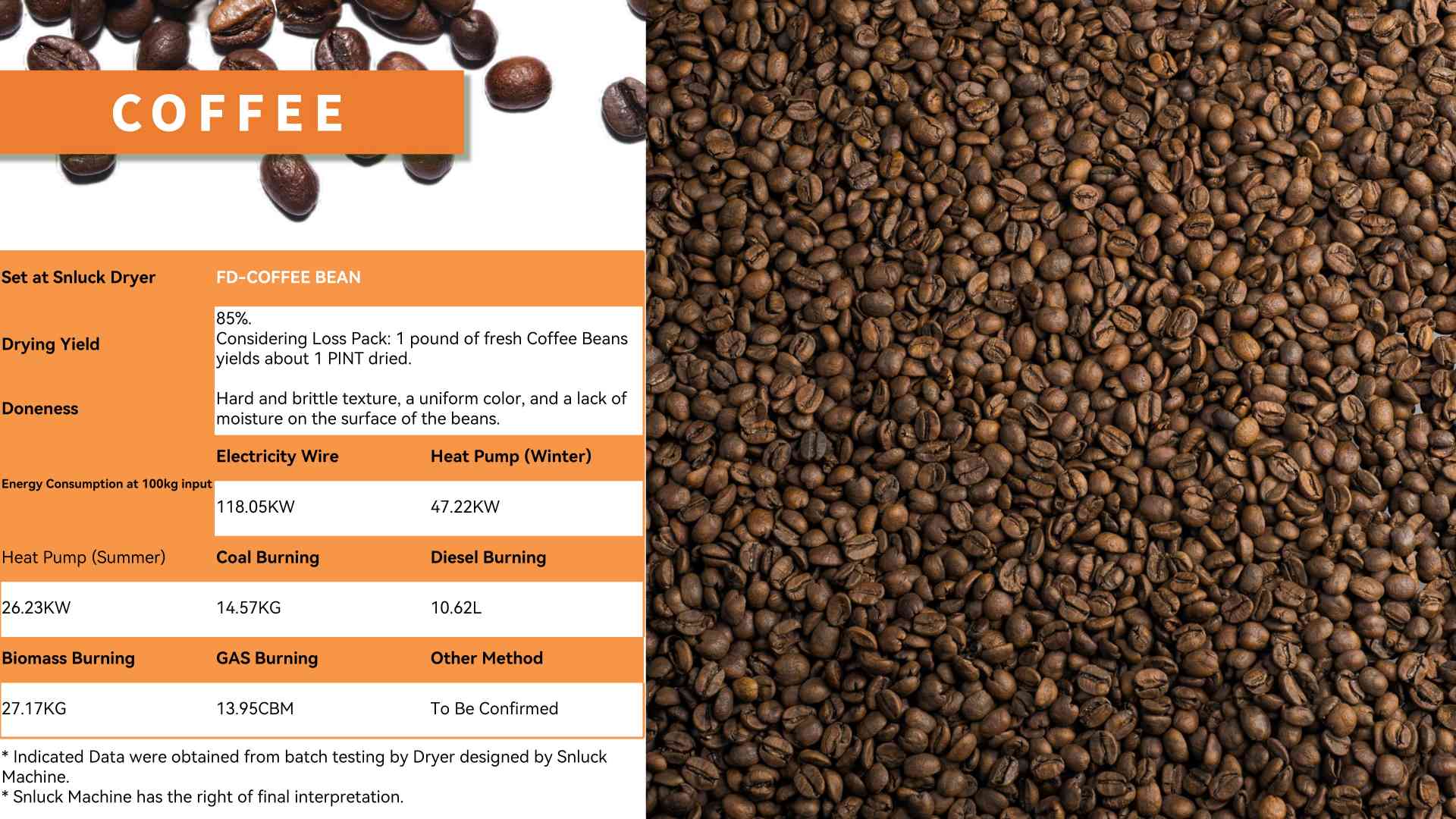

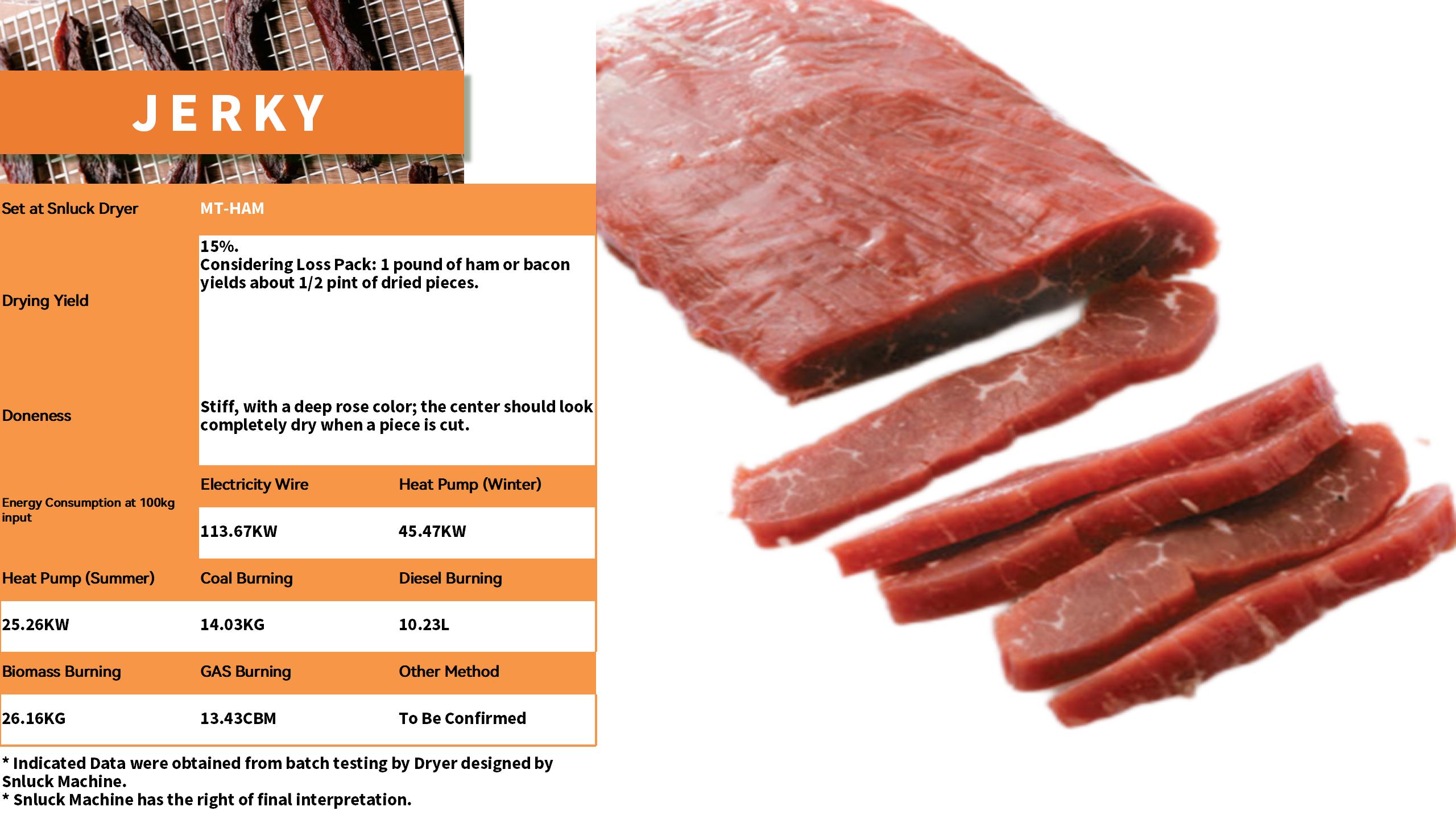

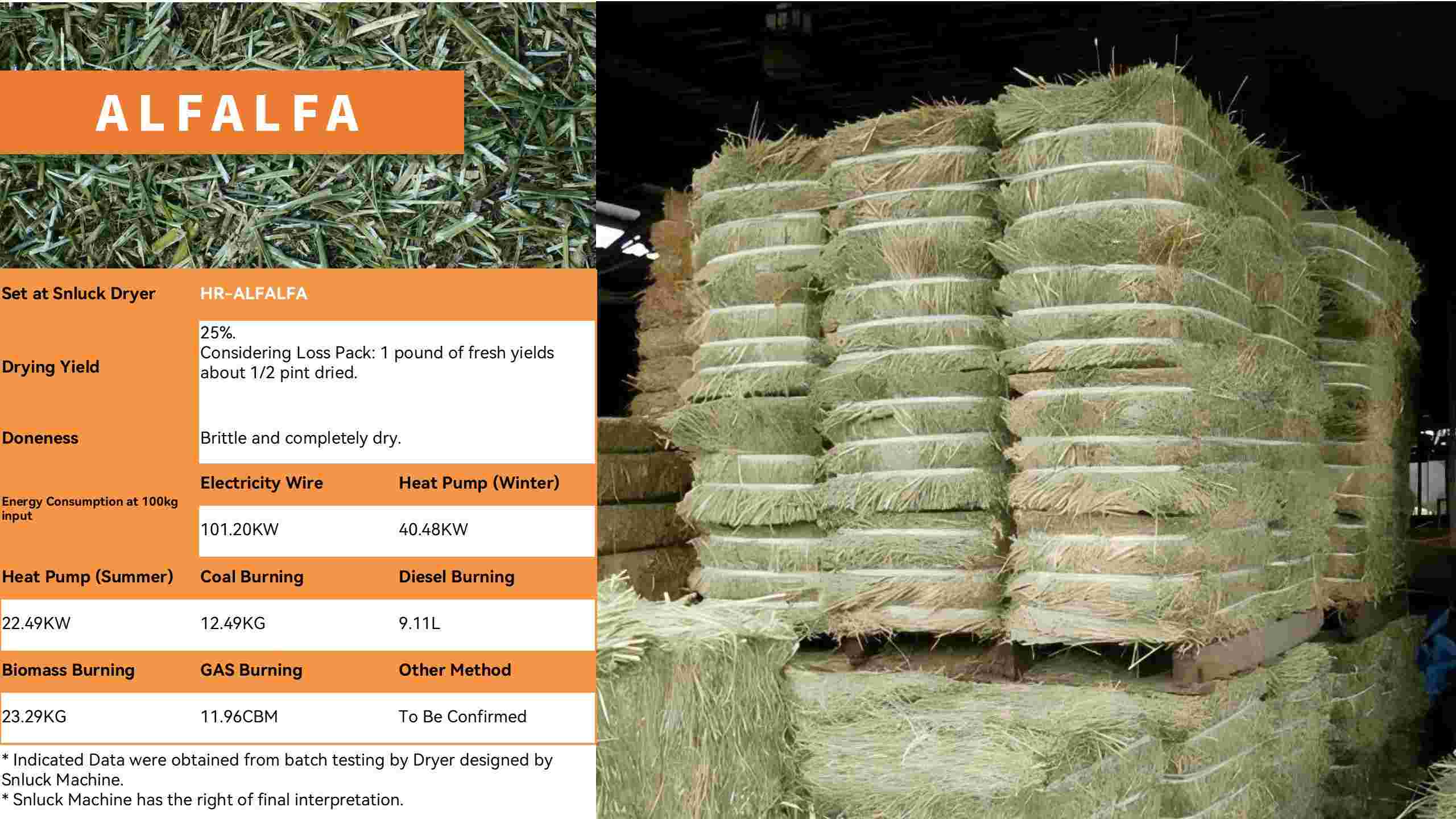

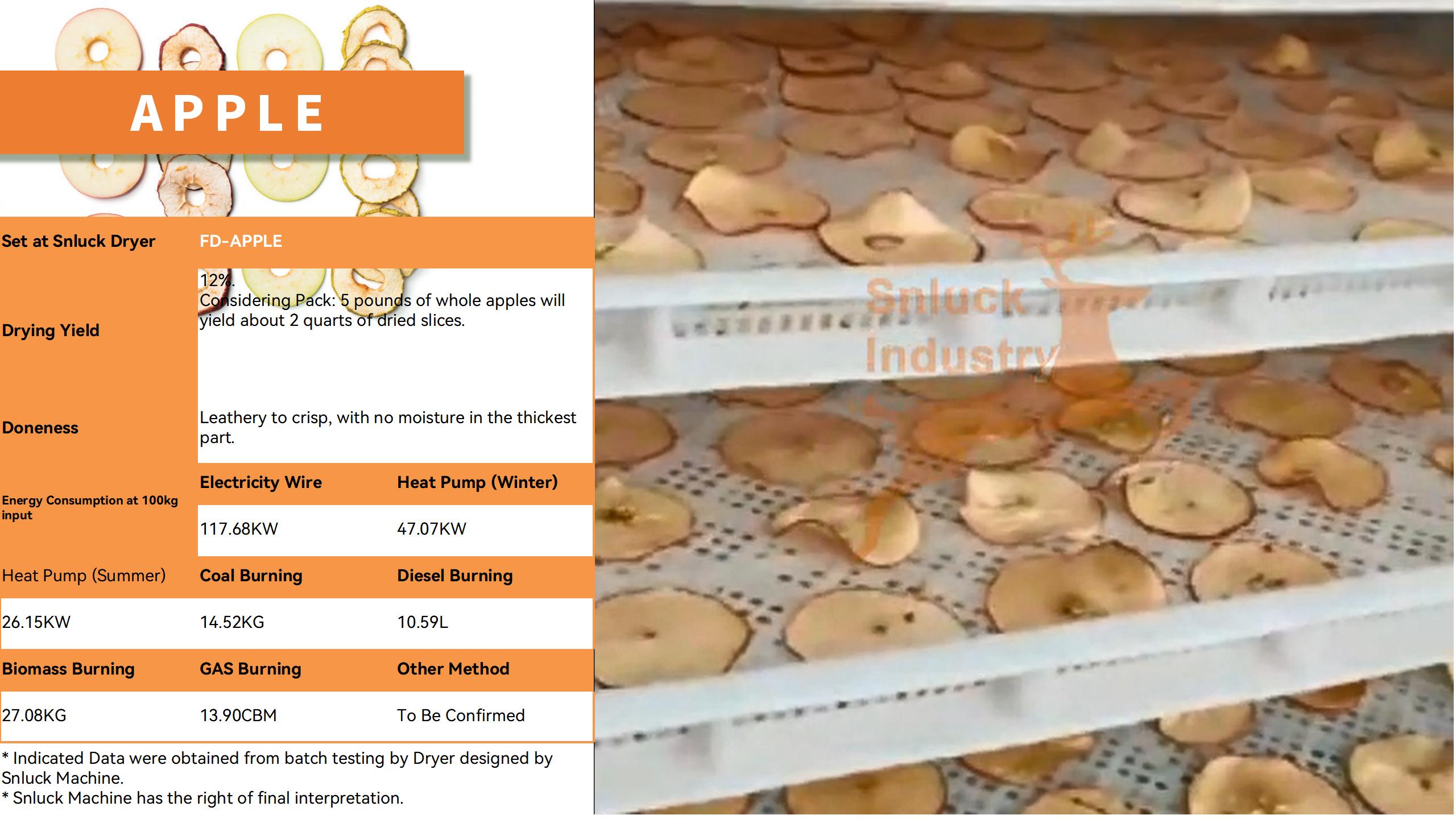

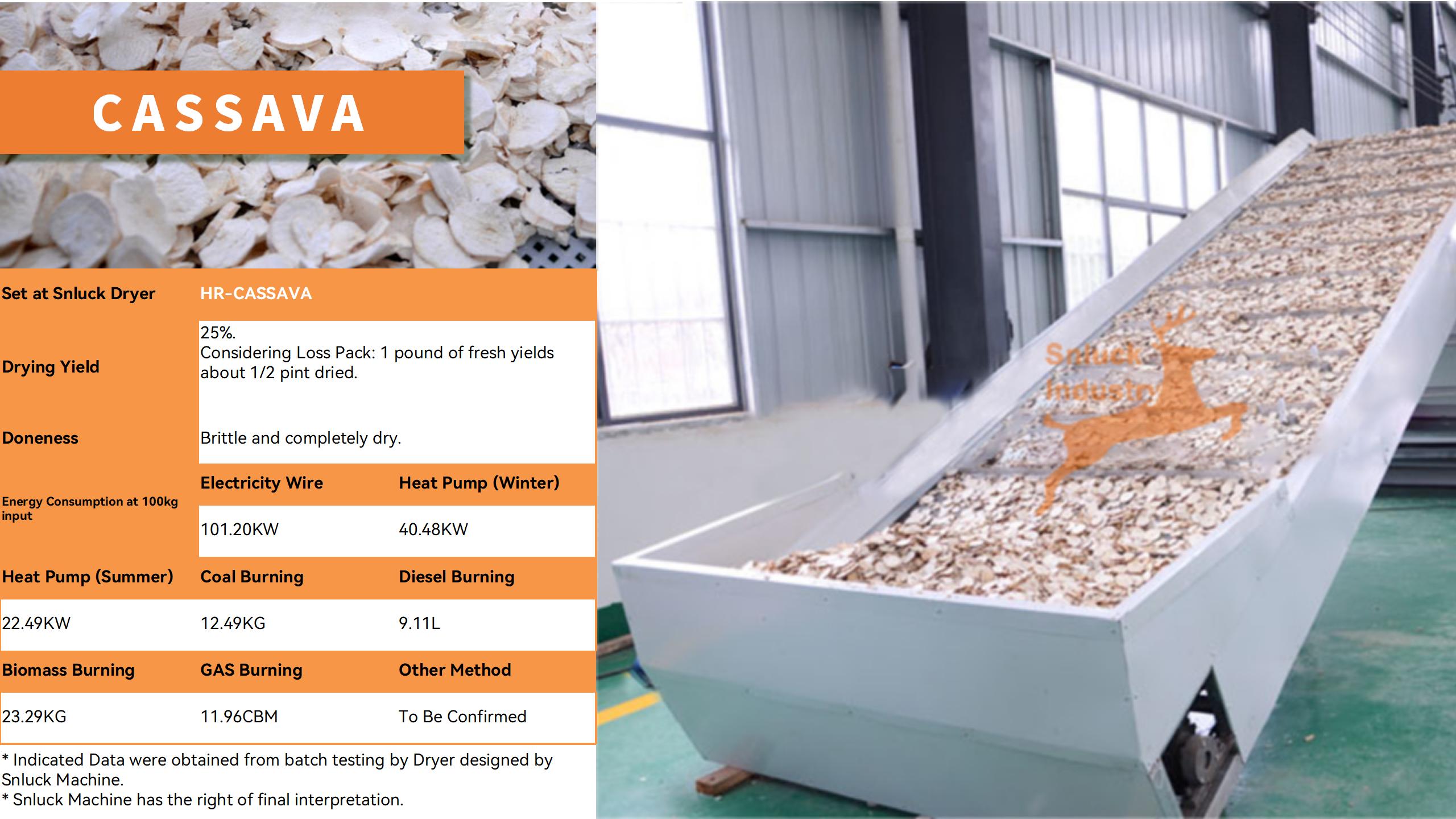

Wide Material Range: Up to 104 Materials Available.

- 2

Adjustable Scale: 300Kg to 50 MT Daily Capacity Single Set

- 3

Power-off Memory: Auto Recovery Function

- 4

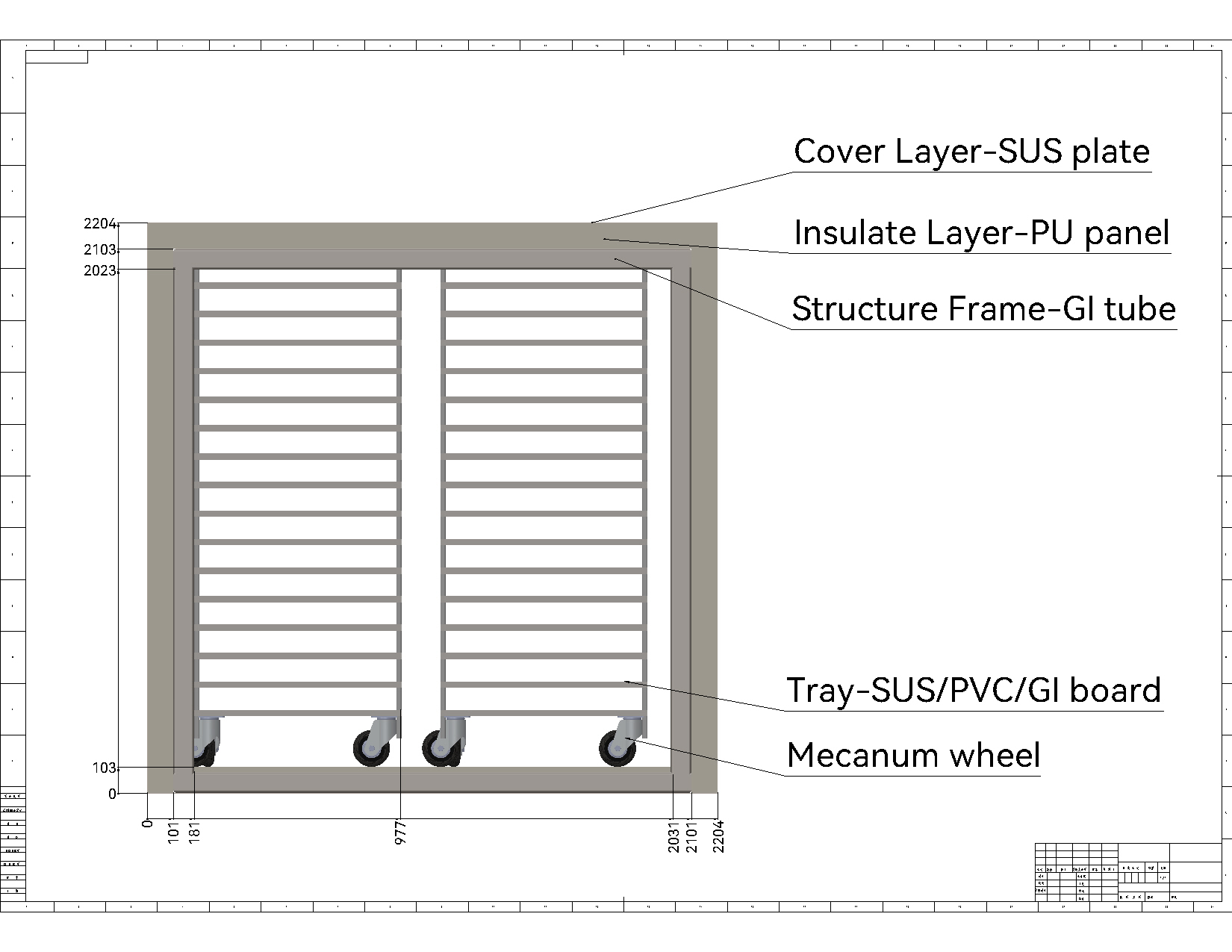

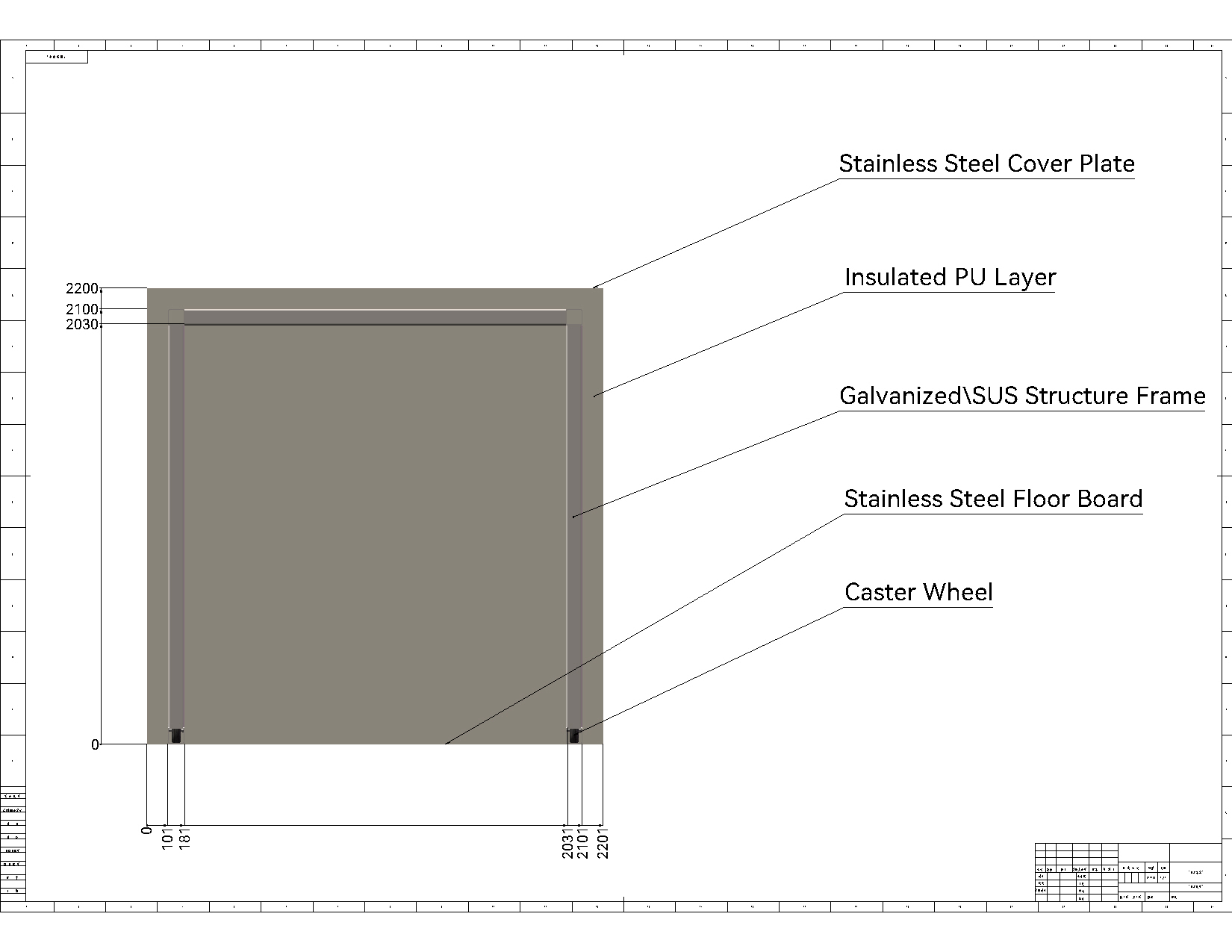

Batch In/Out: Manual Load & Discharge System with Even Spreader

- 5

Minimized Break: Breakage Ratio <3%

- 6

Color & Nutrious Protect: Accurately Temp & Humi Control

- 7

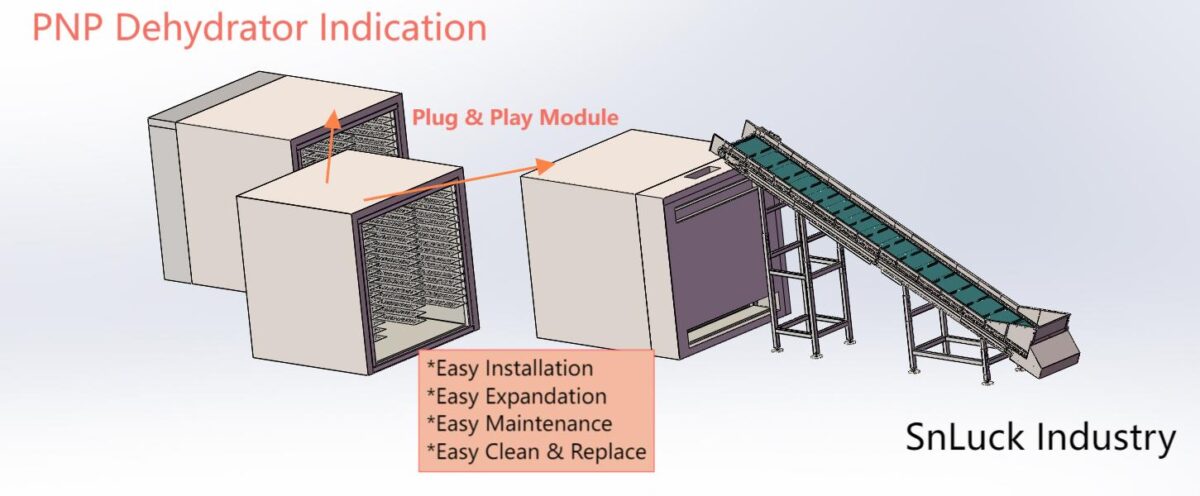

Extendable Plant: Module Add or Replace in 2 Hours

- 8

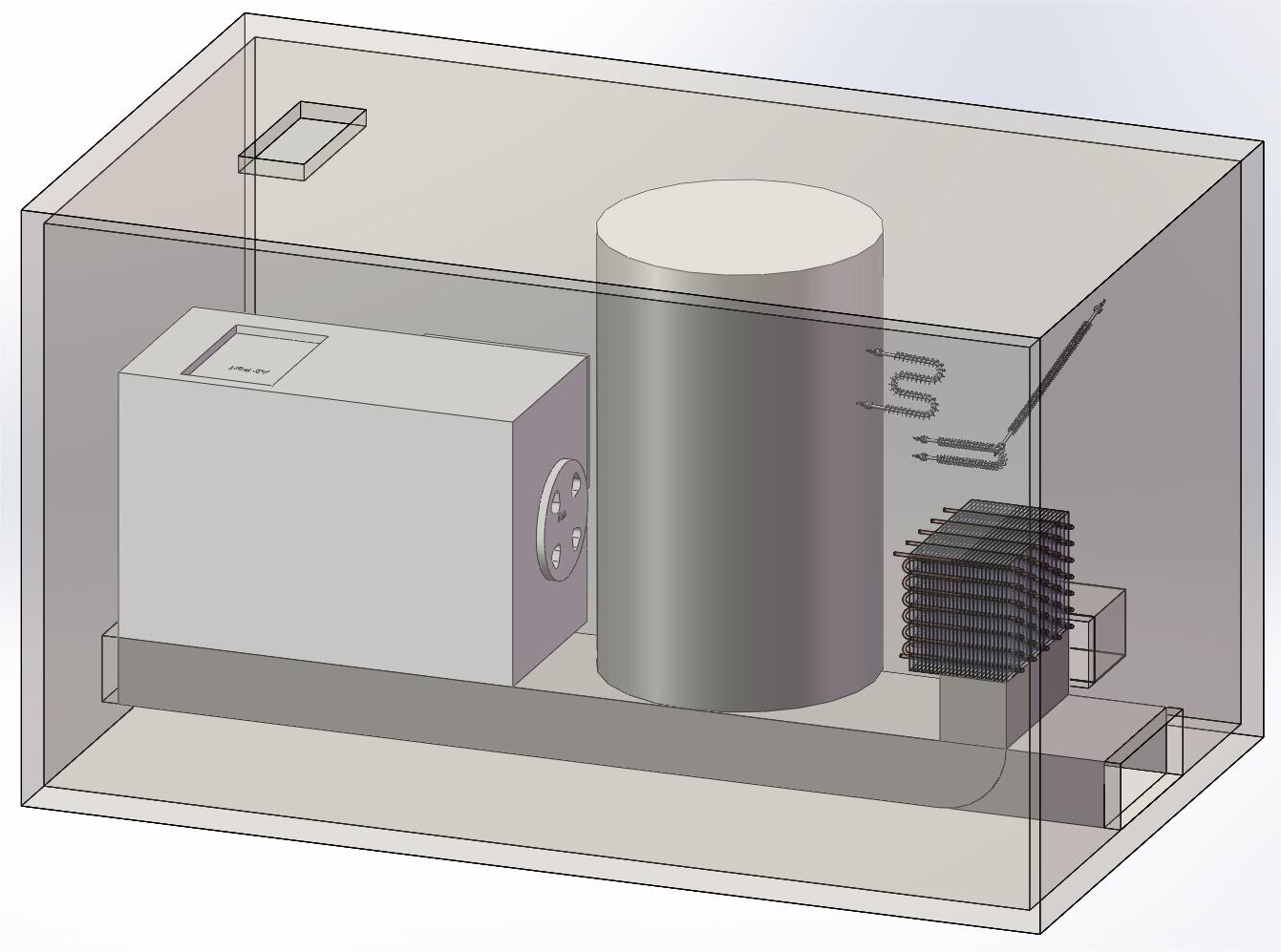

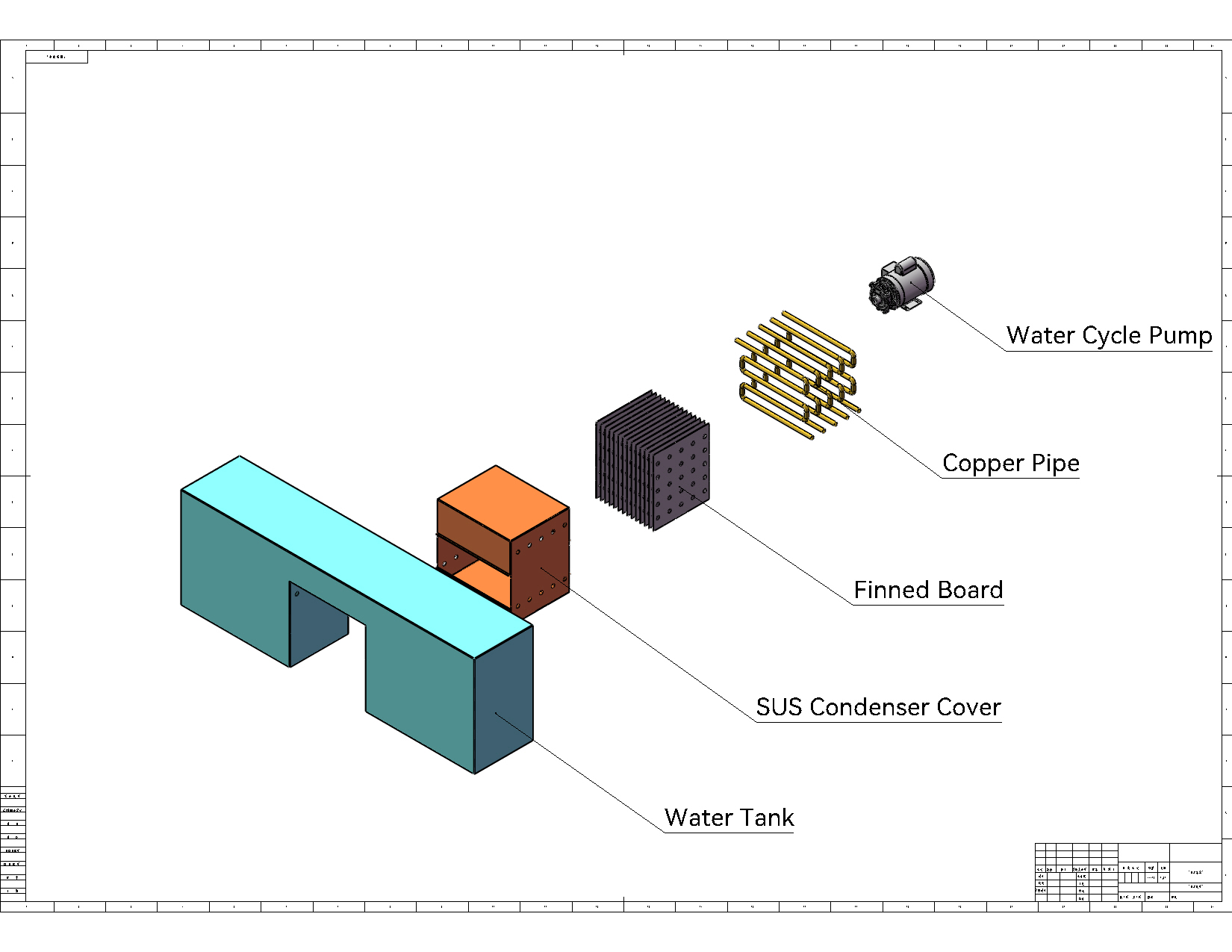

Eco Produce: ConDry™ Technique for Energy Saving

- 9

Produce Data Record: 6 Months Data Storage & Analysis

MBD Module

72-hour Installation Time & 300% Capacity ScalabilityPlug & Play Module

IOT Control

Max Throughput: 13.2t/h | Energy Use: 1.08kW·h/kgIntime Monitering Data

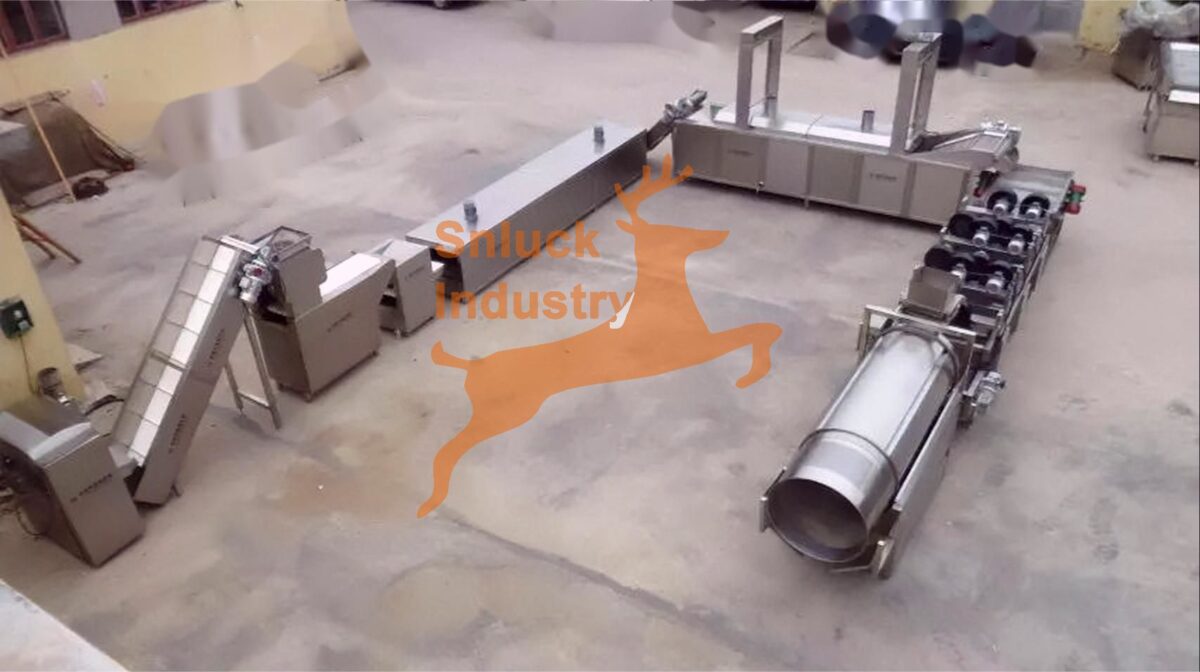

Holistic Line

OPC UA | Profinet | EtherCAT | All 7 Process JointFull Process Production

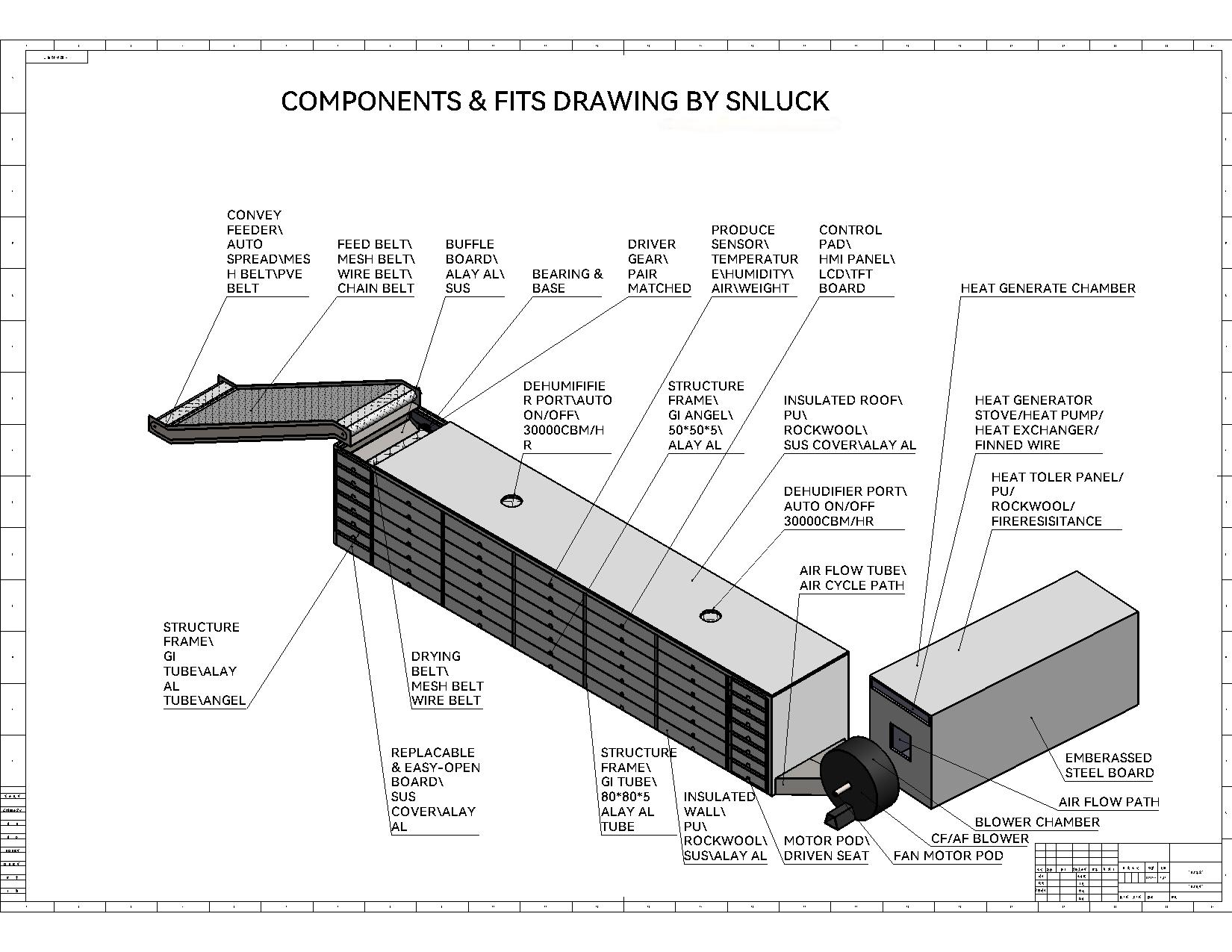

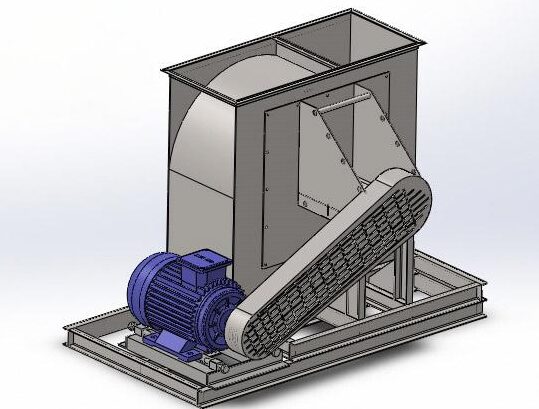

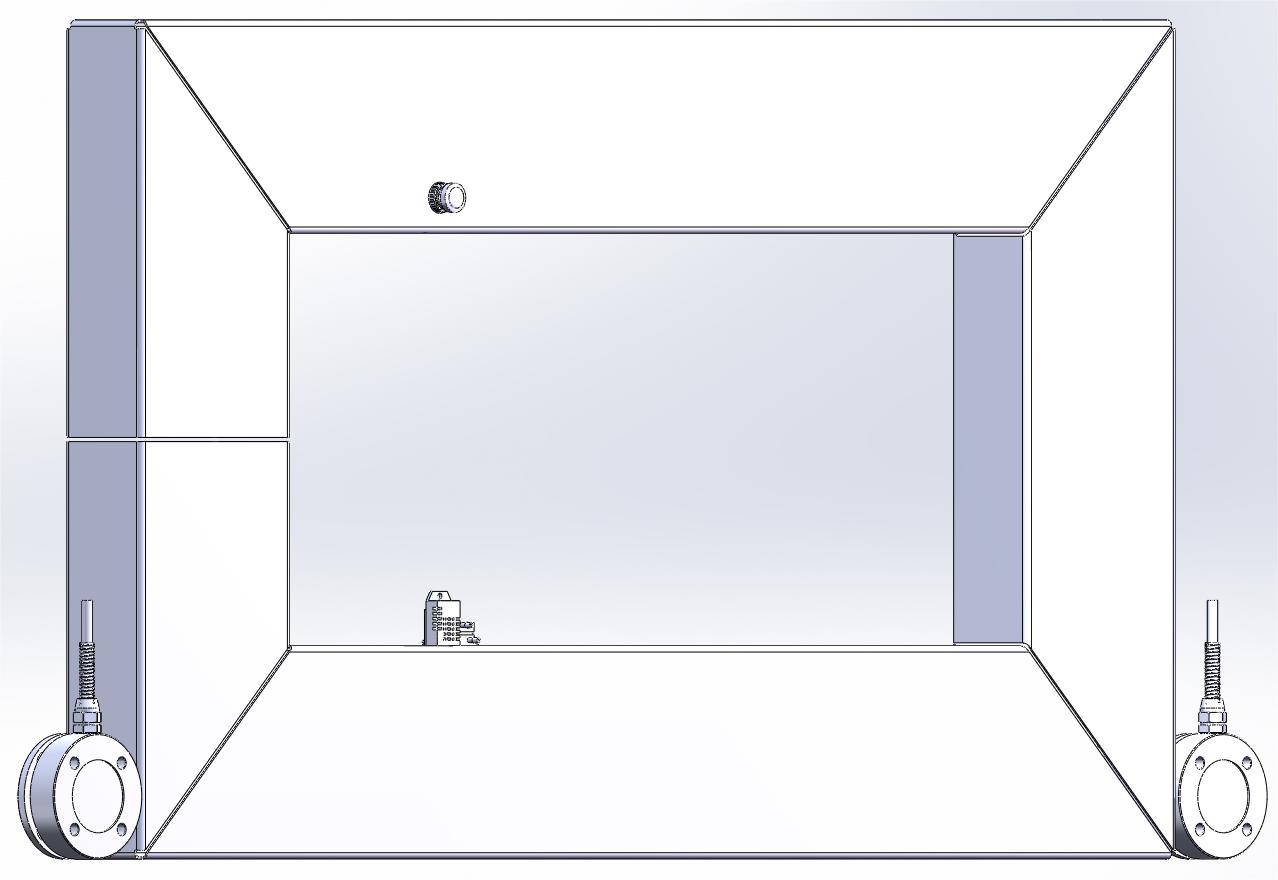

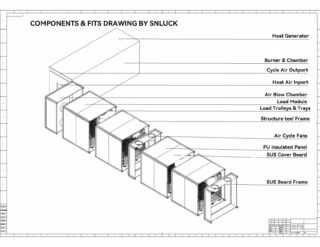

Streamlined Structure of Batch Dryer -

Neat Modules & Parts

Better Result of Batch Dryer By -

Shape, Color, Nutritious

Lower Cost of Batch Dryer By -

Cost, Consumption, Labor

Easier Operating of Batch Dryer By -

In & Out, Set & Check, Expand

Models & Customization of Batch Dryer -

Specification Comparison

| Item | Standard Model SL-CRSX-52 | Rehanced Model SL-CPCX-C2 |

|---|---|---|

| **Regular Parameter** | ||

| Capacity | 400-800Kg/Full | 1200-2400Kg/Full |

| Hot Air Temp Range | 40-120℃ | -15-135℃ |

| Load Layers | 3-18 Layers | 3-18 Layers |

| **Structural Feature** | ||

| Valid Area | 100SQM | 250SQM |

| Thickness Loading | <25mm | <50mm |

| Module Assemble Period | 2Hr | 2Hr |

| **Heat Efficiency** | ||

| Heat Power Efficiency | 78% | 82% |

| Heat Recycle Ratio | 65% | 77% |

| **Control Accuracy** | ||

| Temp Fluctuation Control | ±2℃ | ±1℃(PID 2.0) |

| Humi Fluctuation Control | ±2%MC | ±1%MC |