SnLuck Knows Value of Cassava Industry –

Cassava Market Sheet

Global Cassava Harvest Production

*Data from FAO 2024(Food and Agriculture Organization of the United Nations)

Cassava Production Price

*Data from Domestic Market Commidity Price in China Dec. 12 2024..

From Fresh Cassava to Global Commodities – A Complete Solution for Value-Added Cassava Processing

Breakage rate < 3%

Consumption reduced 23%

EU compliance rate 99%

| ⚑ Industry Pain Points | ✓ Technical Countermeasures | ★ Practical Solution |

|---|---|---|

| Uneven drying | ✔ Multi-dimensional airflow distribution system | ⛆ Air volume & Pressure Control System |

| Difficulty in controlling browning | ✔ Three-stage temperature control curve | ❄ Temp & Humi Intelligent System |

| Poor equipment expandability | ✔ MBD modular structure | ⚯ Modular Assmbling System |

Great Result matters All –

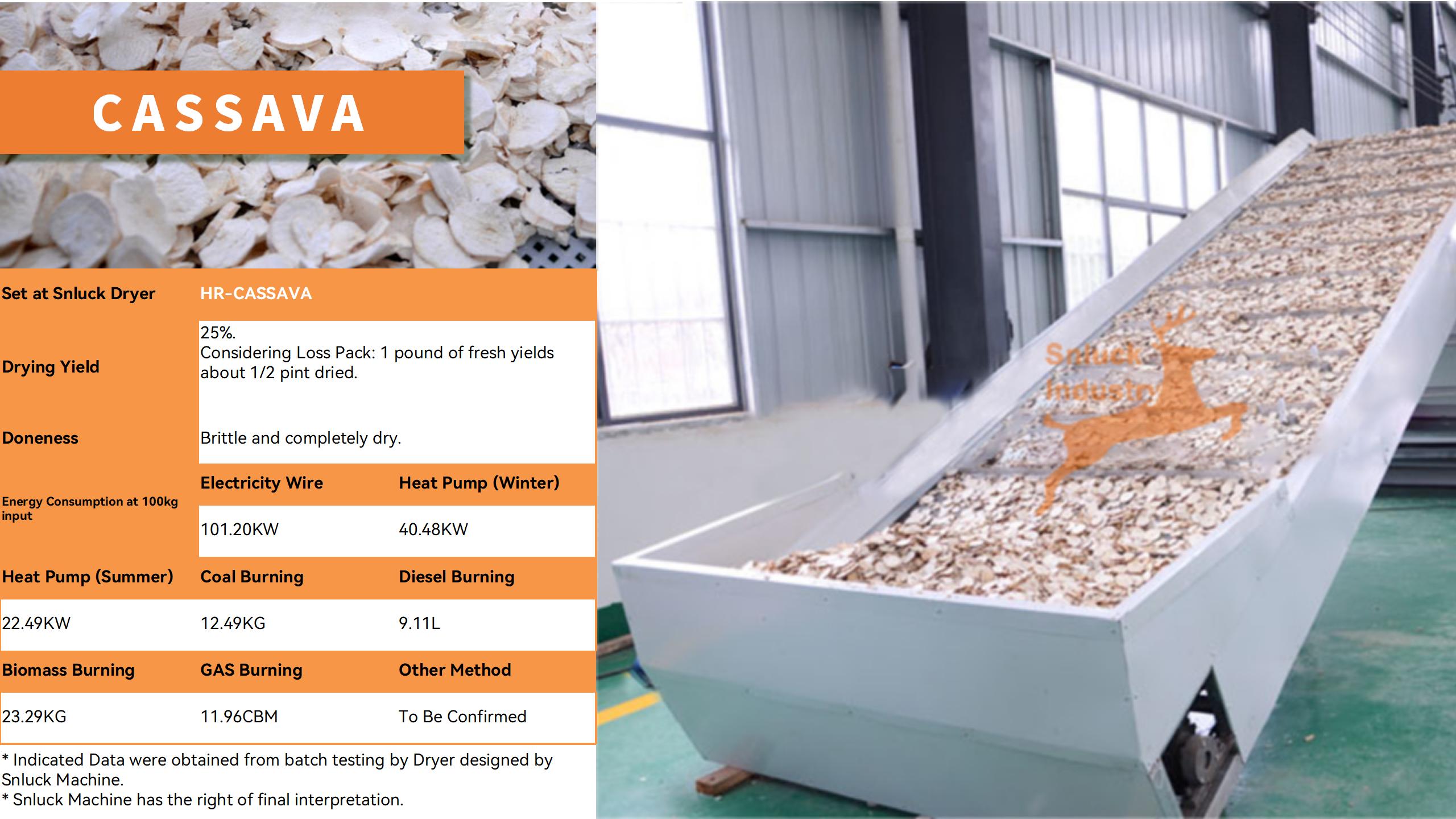

cassava Chips Drying

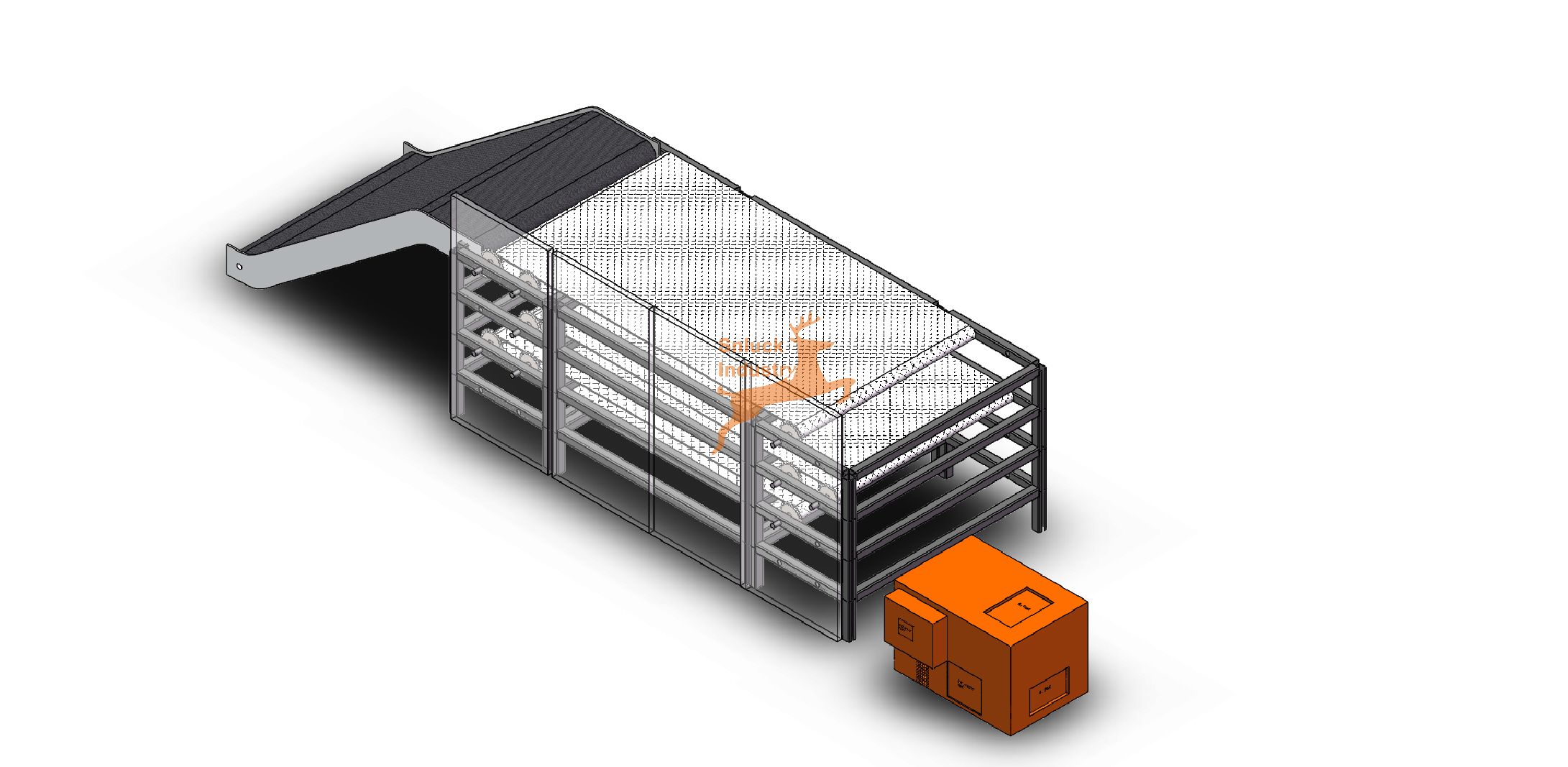

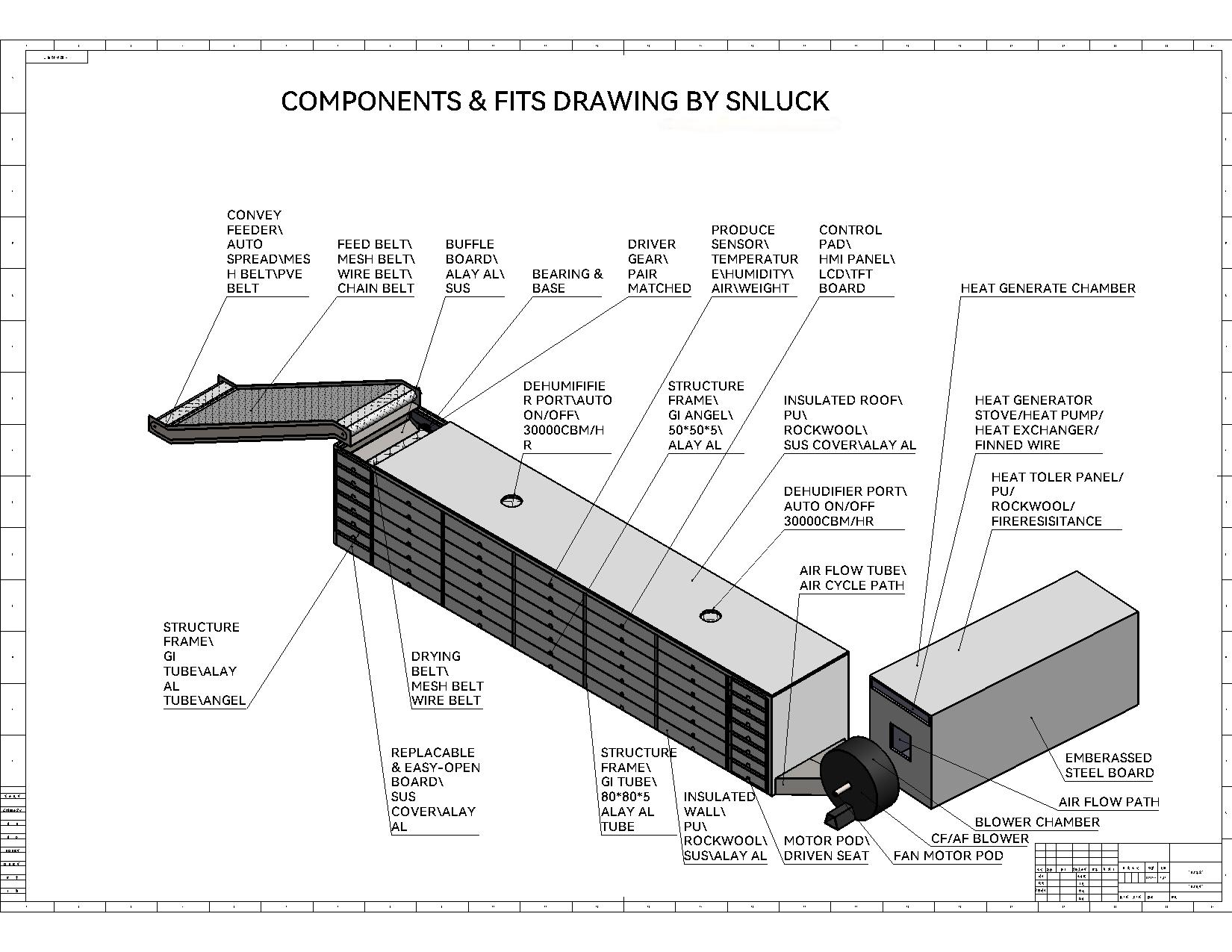

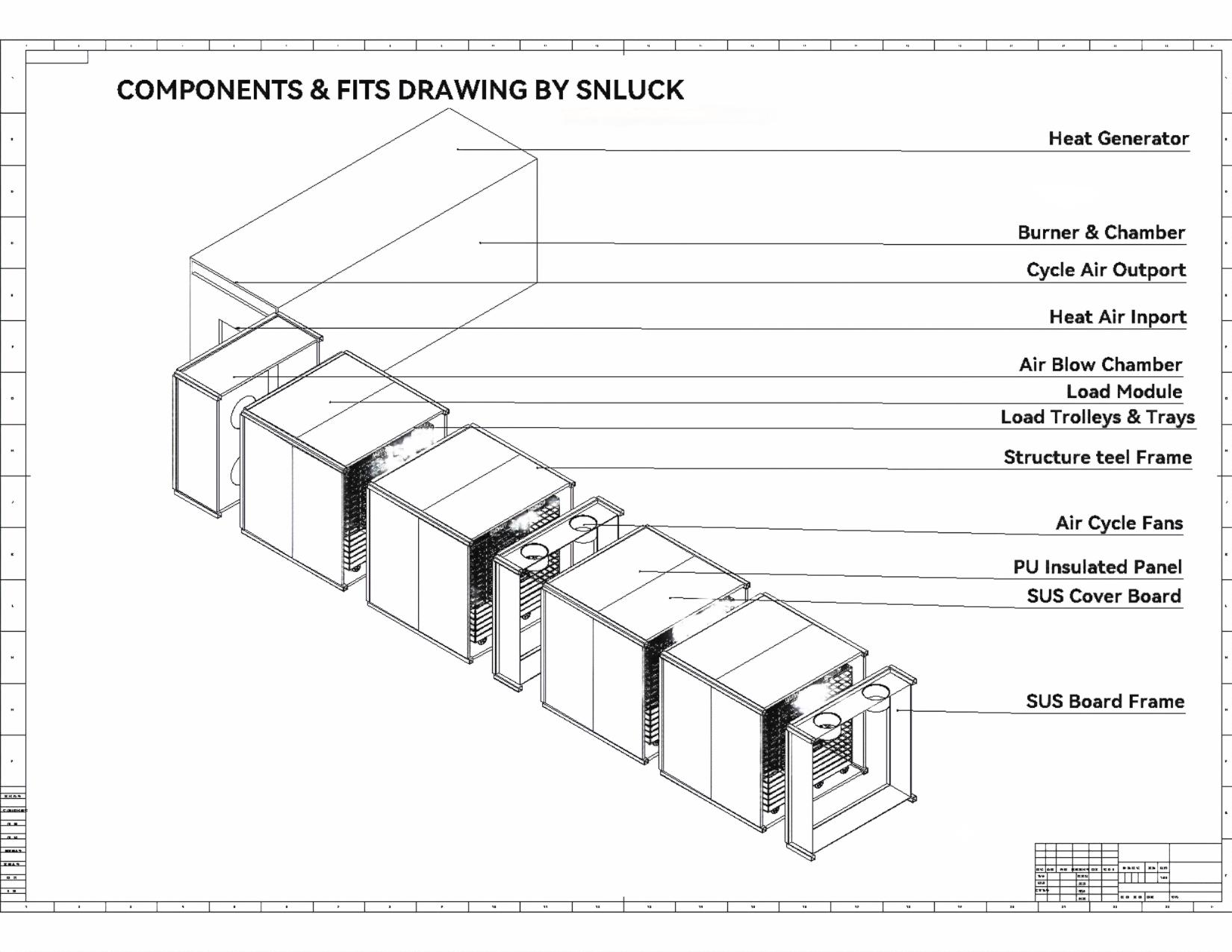

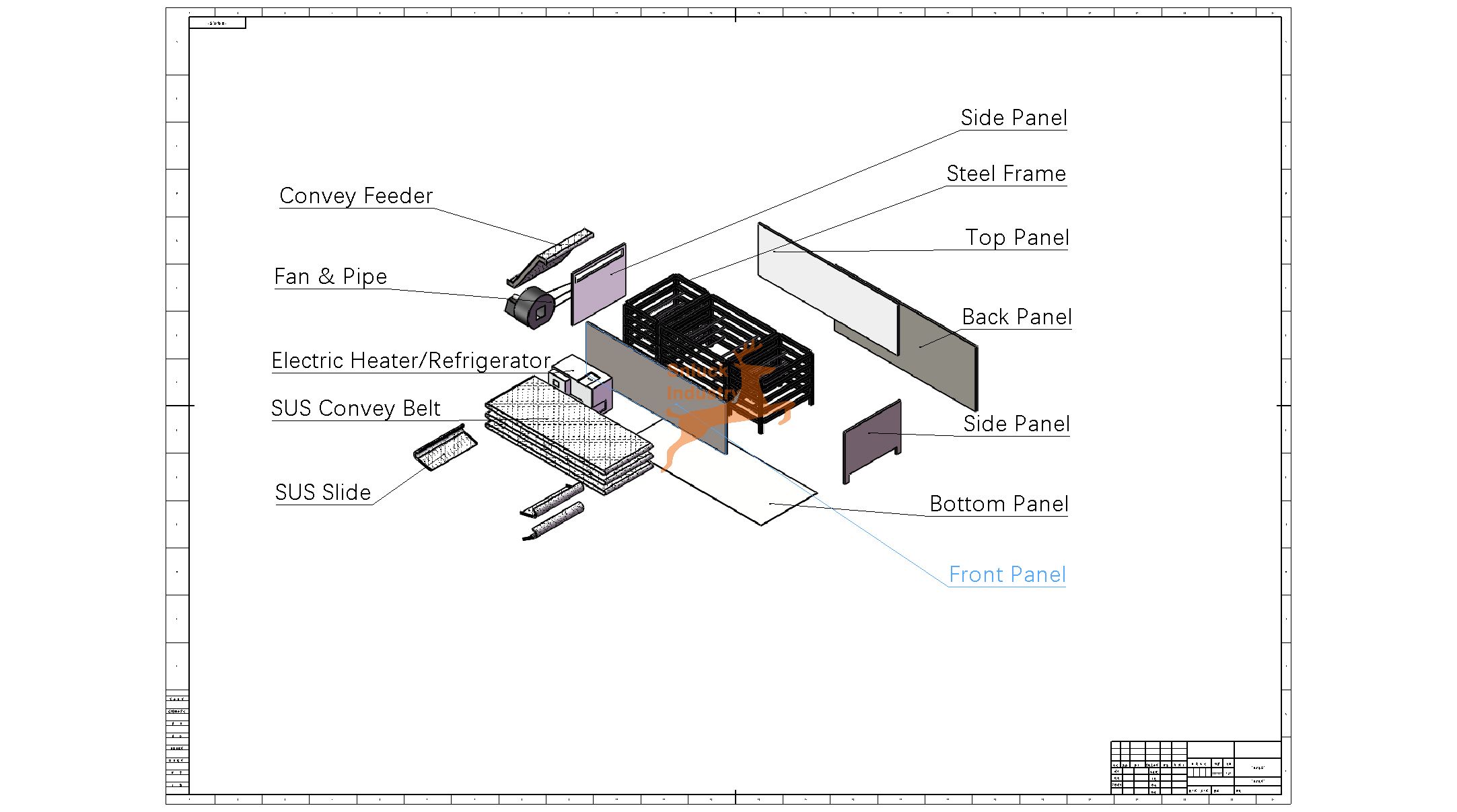

standard Dehydrator Models for Continuous & Batch working –

| Model | SL-CP-L2-WB-AF22-BR (Continuous type) |

|---|---|

| Type of drying | 4 hours per cycle. Daily expect to get 888.89 Kg well dried. Yield Rate: 8.89%. Each hour operate fresh: 416.67Kg. |

| Full Load Range | 500Kg TILE stacking to 1000Kg PILE stacking. 2 Load Module with 16 convey-dry layers. Valid dry-load area: 100SQM. |

| Size | 5.8*2.2*2.2 Meter. | Volume: 28.07 Cubic Meter. | Occupied Area: 12.76 Sqm. Convey-dry layer: 2 meter wide, 3-10 mm thickness. Layer Gap: 100mm. |

| Power | Convey power: 0.5Kw. Convey Speed: 18.0m/hr. Air power: 2Kw. Generate airpressure: 520.0Pa, with air speed: 4m/s. |

| Yield | 37.23% – 51.11% |

| Model | SL-BP-L4-WB-AF11-BR (Batch type) |

|---|---|

| Type of drying | 8 hours per batch. Each batch load fresh: 2743.63Kg. Daily expect to get 888.89 Kg well dried. Yield Rate: 8.89%. |

| Full Load Range | 1000Kg TILE stacking to 2000Kg PILE stacking. 4 Load Modules with 432 trays in 24 trolleys. Valid dry-load area: 200SQM. |

| Size | 9.8*2.2*2.2 Meter. | Volume: 47.43 Cubic Meter. | Occupied Area: 21.56 Sqm. Unit Trays Size: 800*600*30mm. Trays Gap: 100mm. |

| Power | Air power: 1Kw. Generate airpressure: 584.0Pa, with air speed: 4m/s. |

| Yield | 37.23% – 51.11% |

Accurate & Intelligent Control System –

Drying Controls

45-65℃

15-65%

6-12 hr

Pile load

Pre-treatment features cleaning, skin rubbing and scraping to thoroughly clear fresh cassava’s surface and remove its skin.

Cleaning Process Machine

- Key Equipment:Equipped with an eddy current stone removal machine and a high-pressure spray tower to efficiently remove impurities, laying a solid foundation for subsequent cassava processing.

- Core Indicators:Impurity residue ≤ 0.2%, ensuring the high cleanliness of cassava; the cleaning water recycling rate ≥ 85%, saving water and reducing costs.

Peeling Process Machine

- Key Equipment: Roller Skin Rubbing Machine. With the steel brushes, abrasives on the drum or the rotating brush rollers, it strongly scrapes cassava.

- Core Indicators: The peeling rate is ≥ 95%, ensuring thorough skin removal; the failure shutdown rate is ≤ 1%, ensuring stable and continuous production.

Shaping equipment like slicers , section cutters, dicers, grinders, crushers, and pelletizer play vital roles in transforming raw cassava into diverse forms to meet different production demands and enhance processing efficiency and quality.

breaking Process Machine

- Slicing Thickness: 2-5(±0.3mm) (in accordance with GB & FDA & EU standards)

- Grinding Finess: 80-100 mesh

- Dicing Size: 2-5mm

- Pellet Size: 2-50mm

Shaping Process Machine

Support more than just delivery

Service & Support

- 1

Seamless transaction: Minimizes administrative hassles for a smooth purchase.

- 2Timely delivery: Guarantees equipment arrival as scheduled for prompt production or operation start.

- 3Efficient installation and commissioning: Provides technical support for quick and correct equipment setup.

- 4Comprehensive training: The 15-day training equips users to operate and maintain the equipment effectively.

- 5Prompt technical issue resolution: Enables quick troubleshooting and minimizes downtime.

- 6Risk-free initial operation: The three-month trial operation helps identify and address potential issues for stable performance.

- 7Cost-effective maintenance: Offers maintenance advice and cost-effective spare parts and servicing.

- 8Continuous improvement: Enhances equipment and services based on feedback for better value.

- 9Long-term partnership: Builds a reliable relationship for ongoing support and mutual success.