Great Result is all that matters –

Well-Do Produce

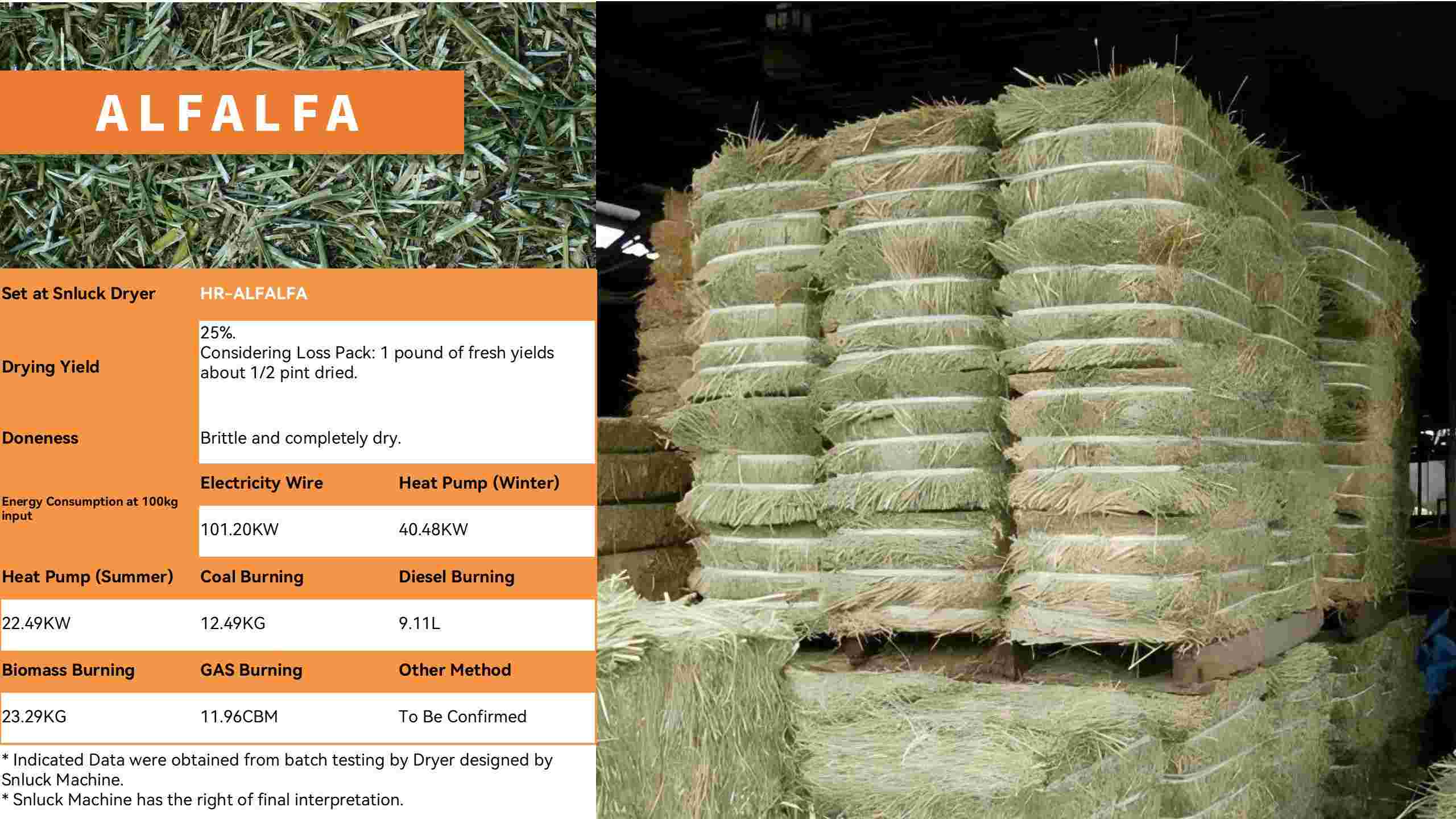

Alfalfa Hay always are used for –

Prepare-Shape-ValueAdd-Pack Machines

Process Line

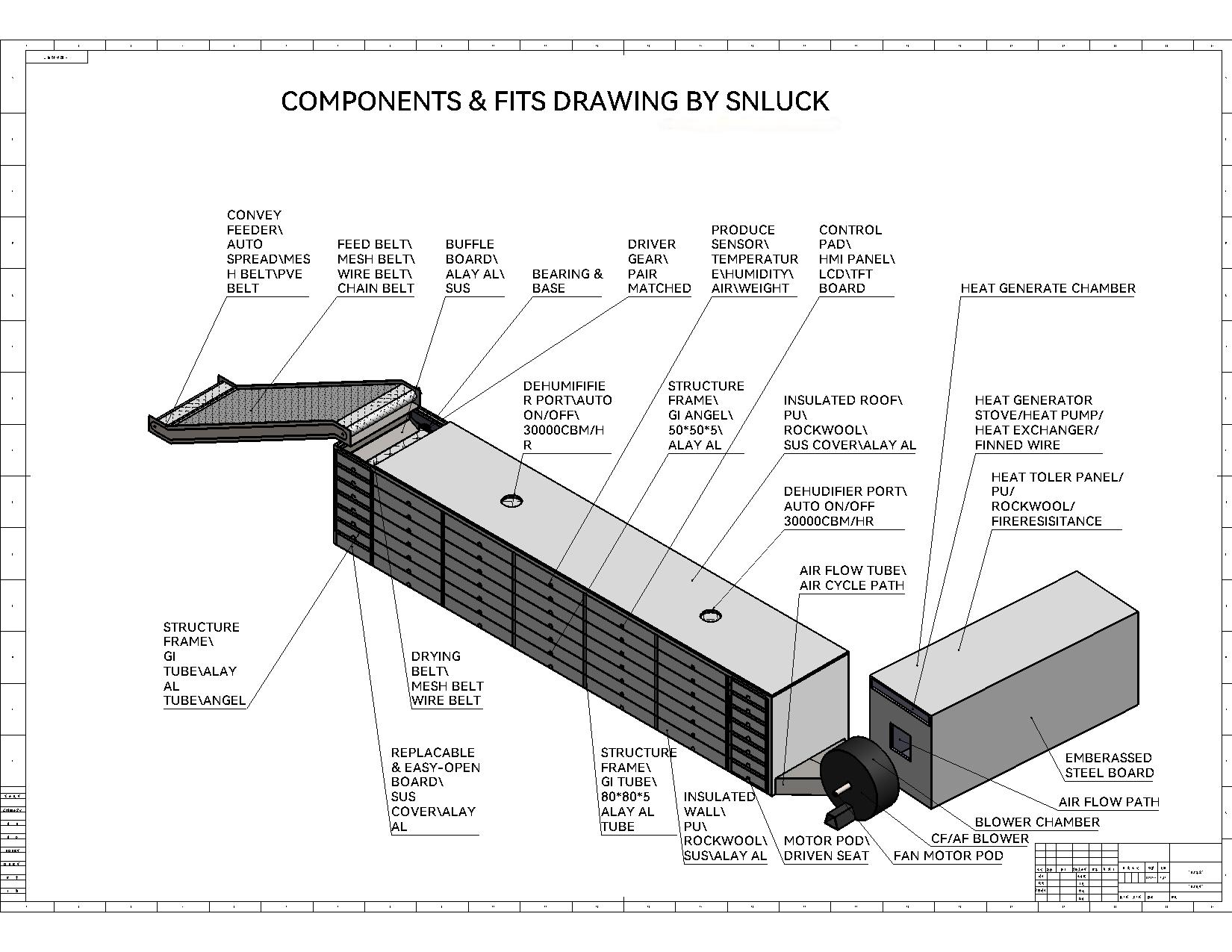

Continuous & Efficient Equipment by SnLuck –

Continuous Drying plant

Produce Instruction

| Model | SL-CP-L2-WB-AF22-BR (Continuous type) |

|---|---|

| Type of drying | 4 hours per cycle. Daily expect to get 888.89 Kg well dried. Yield Rate: 8.89%. Each hour operate fresh: 416.67Kg. |

| Full Load Range | 500Kg TILE stacking to 1000Kg PILE stacking. 2 Load Module with 16 convey-dry layers. Valid dry-load area: 100SQM. |

| Size | 5.8*2.2*2.2 Meter. | Volume: 28.07 Cubic Meter. | Occupied Area: 12.76 Sqm. Convey-dry layer: 2 meter wide, 3-10 mm thickness. Layer Gap: 100mm. |

| Power | Convey power: 0.5Kw. Convey Speed: 18.0m/hr. Air power: 2Kw. Generate airpressure: 520.0Pa, with air speed: 4m/s. |

| Yield | 37.23% |

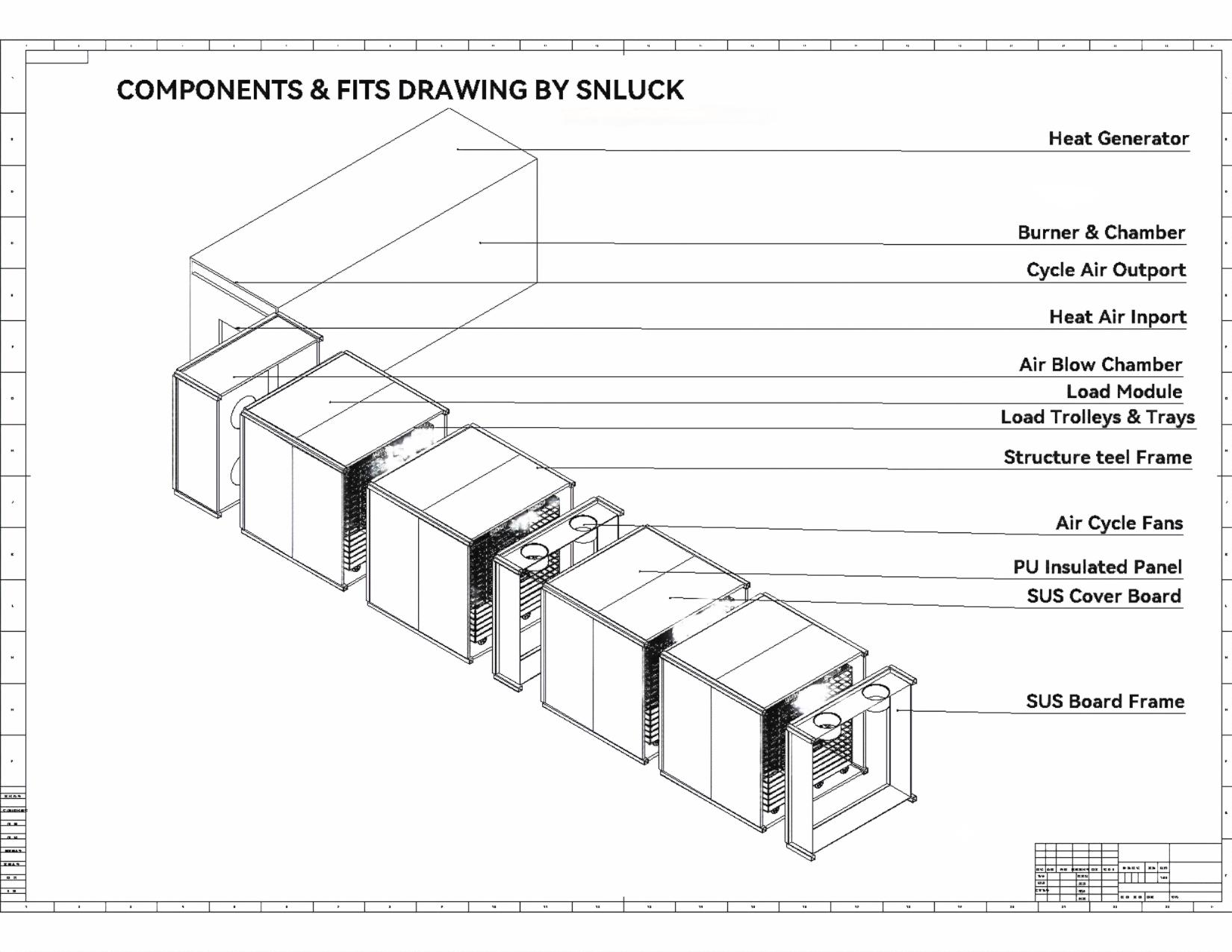

Batch & Reliable Equipment by SnLuck –

Batch Drying plant

Produce Instruction

| Model | SL-BP-L4-WB-AF11-BR (Batch type) |

|---|---|

| Type of drying | 8 hours per batch. Each batch load fresh: 2743.63Kg. Daily expect to get 888.89 Kg well dried. Yield Rate: 8.89%. |

| Full Load Range | 1000Kg TILE stacking to 2000Kg PILE stacking. 4 Load Modules with 432 trays in 24 trolleys. Valid dry-load area: 200SQM. |

| Size | 9.8*2.2*2.2 Meter. | Volume: 47.43 Cubic Meter. | Occupied Area: 21.56 Sqm. Unit Trays Size: 800*600*30mm. Trays Gap: 100mm. |

| Power | Air power: 1Kw. Generate airpressure: 584.0Pa, with air speed: 4m/s. |

| Yield | 37.23% |

The most 3 benefits on Alfalfa Dryer -

Higher & Lower

Higher Return & Lower Expense.

TemperatureHumidityPeriodAirflow Manage

Drying Controls

40-60℃

15-65%

4-8 hr

Tile load

Support more than just delivery

Service & Support

- 1

Seamless transaction: Minimizes administrative hassles for a smooth purchase.

- 2Timely delivery: Guarantees equipment arrival as scheduled for prompt production or operation start.

- 3Efficient installation and commissioning: Provides technical support for quick and correct equipment setup.

- 4Comprehensive training: The 15-day training equips users to operate and maintain the equipment effectively.

- 5Prompt technical issue resolution: Enables quick troubleshooting and minimizes downtime.

- 6Risk-free initial operation: The three-month trial operation helps identify and address potential issues for stable performance.

- 7Cost-effective maintenance: Offers maintenance advice and cost-effective spare parts and servicing.

- 8Continuous improvement: Enhances equipment and services based on feedback for better value.

- 9Long-term partnership: Builds a reliable relationship for ongoing support and mutual success.