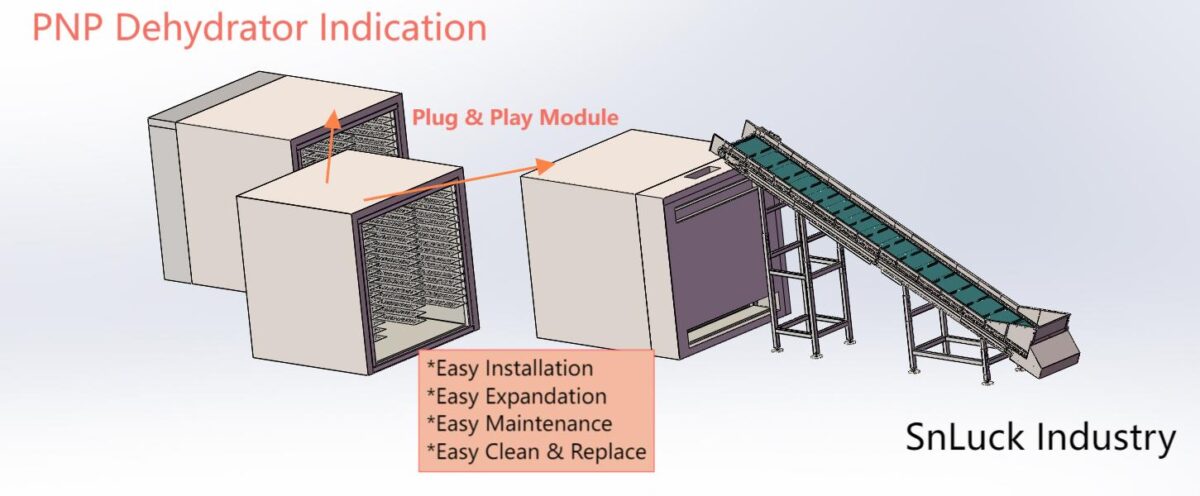

MBD Module

72-hour Installation Time & 300% Capacity ScalabilityPlug & Play Module

IOT Control

Max Throughput: 13.2t/h | Energy Use: 1.08kW·h/kgIntime Monitering Data

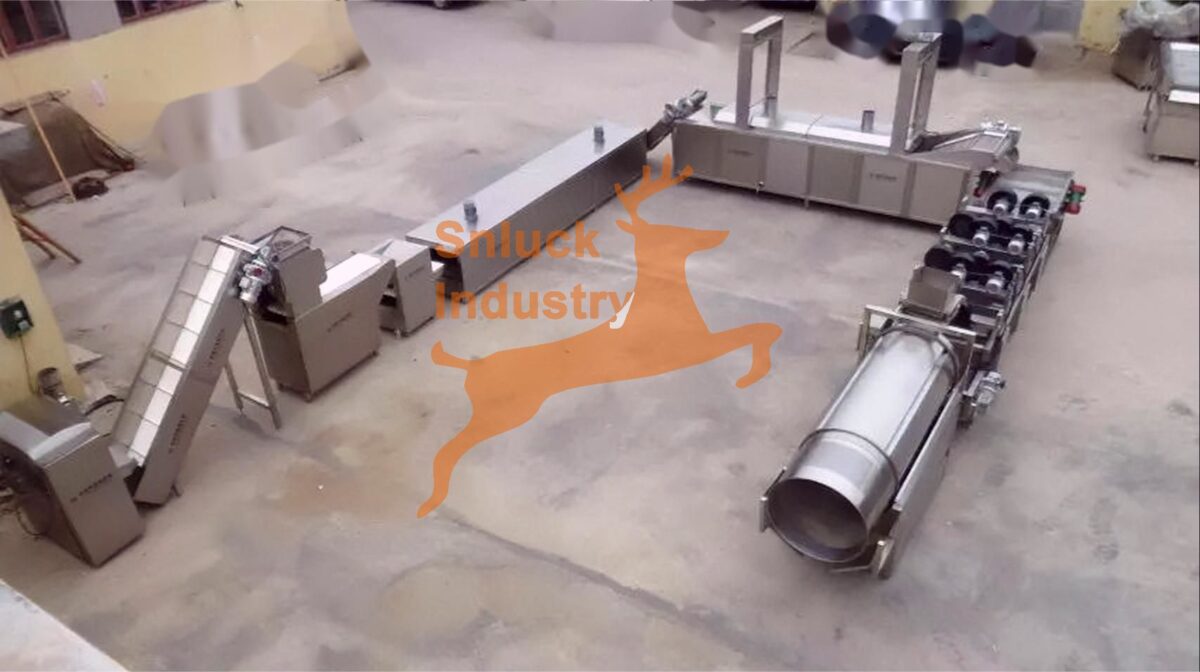

Holistic Line

OPC UA | Profinet | EtherCAT | All 7 Process JointFull Process Production

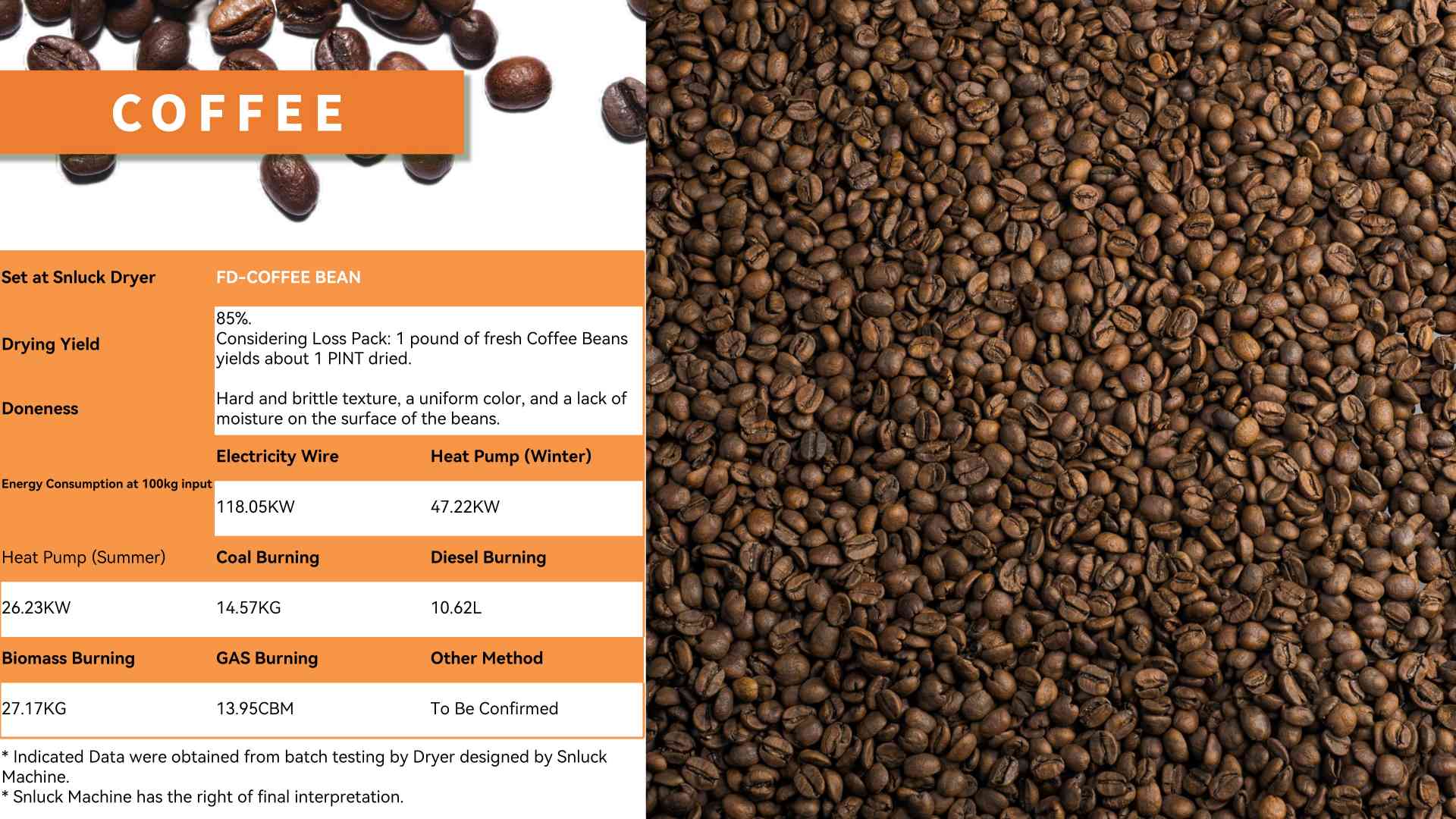

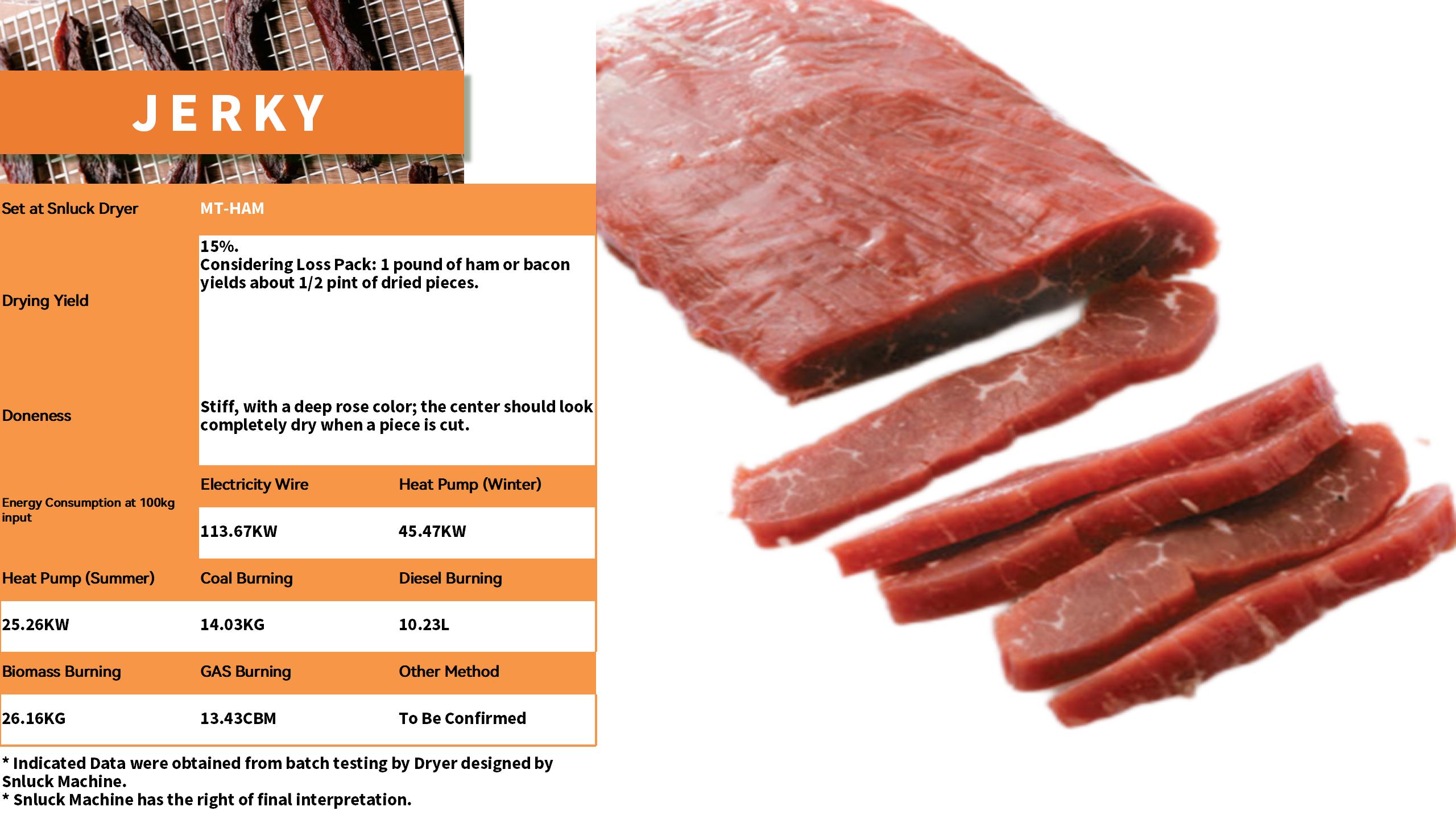

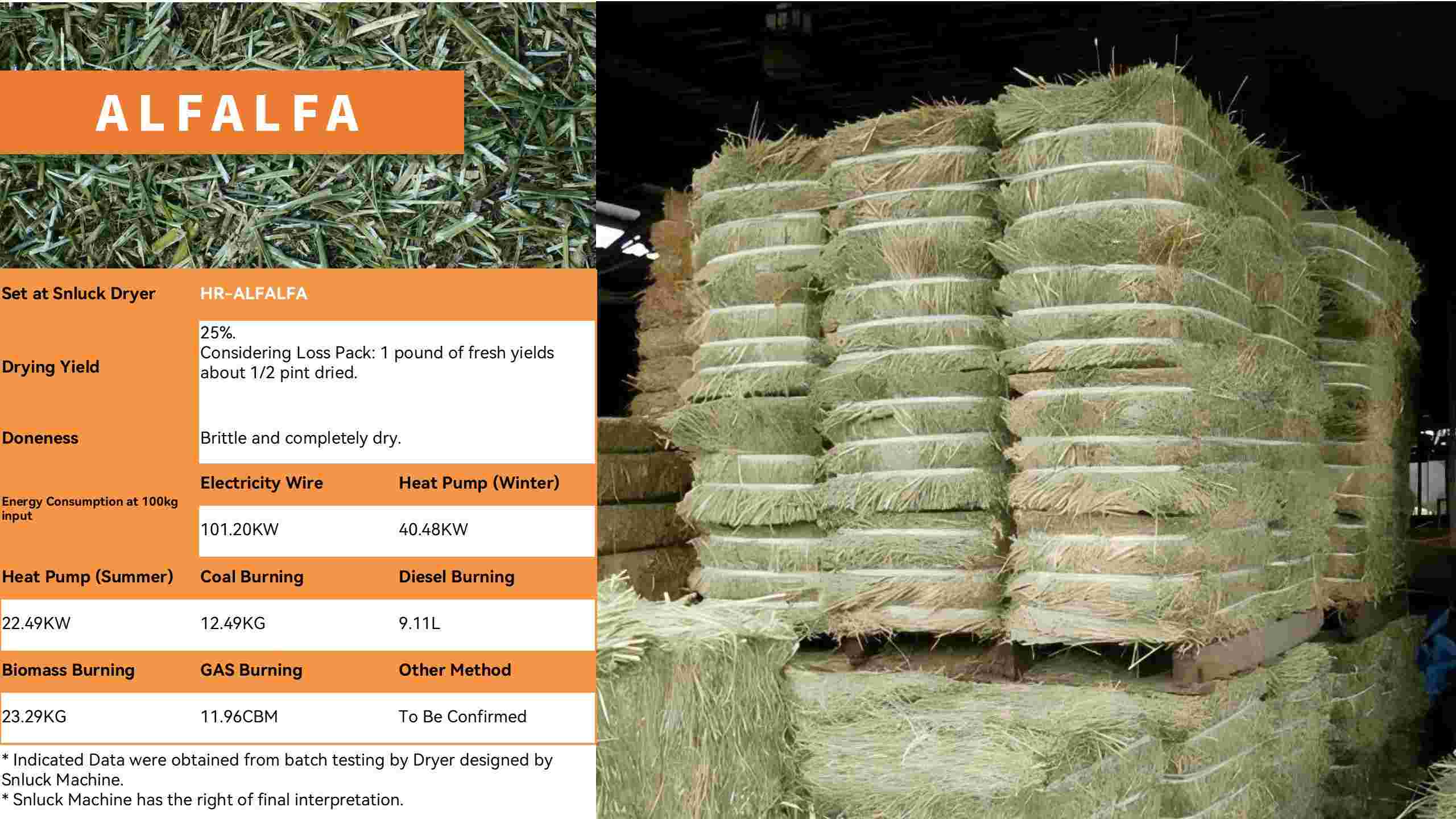

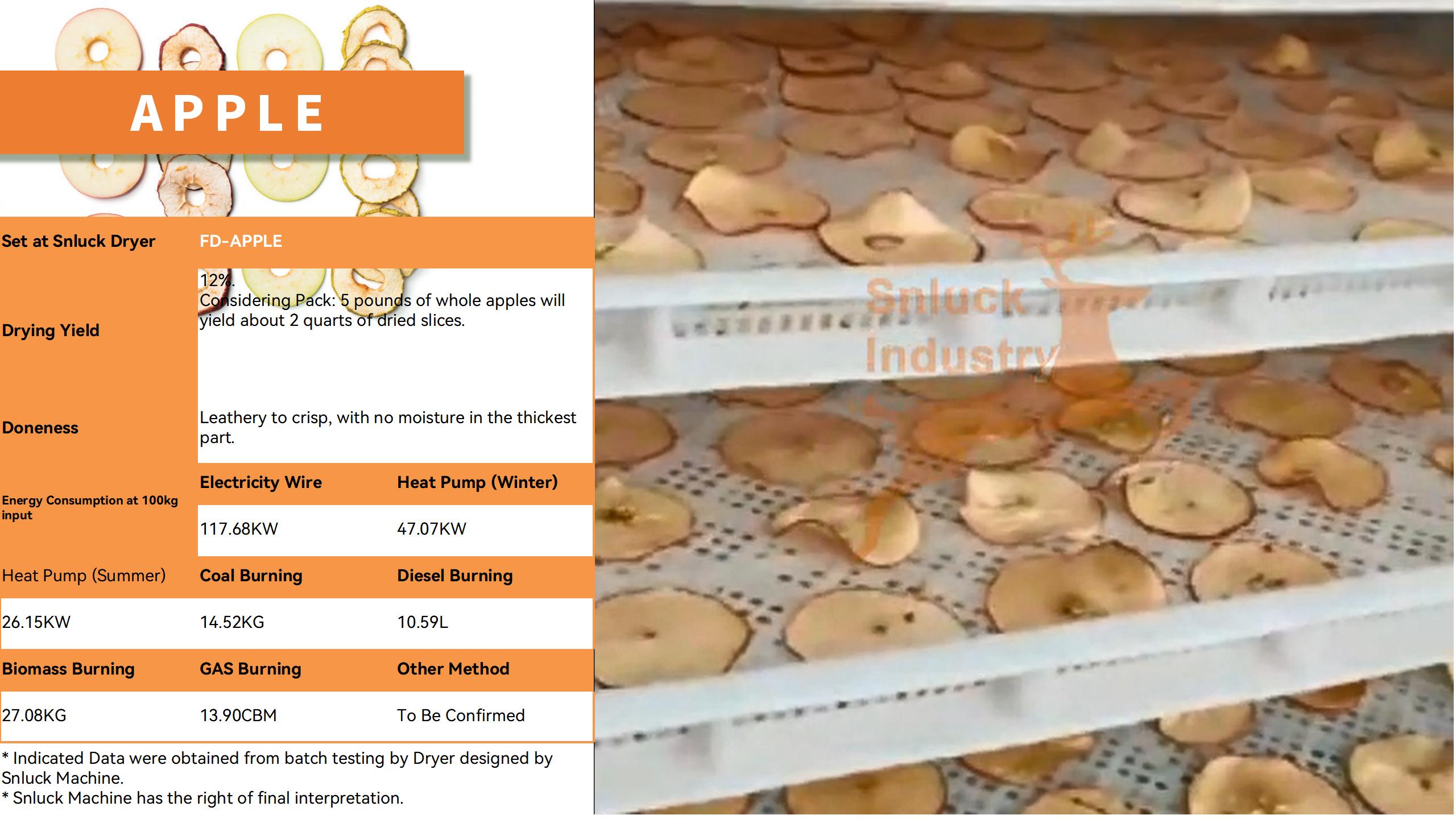

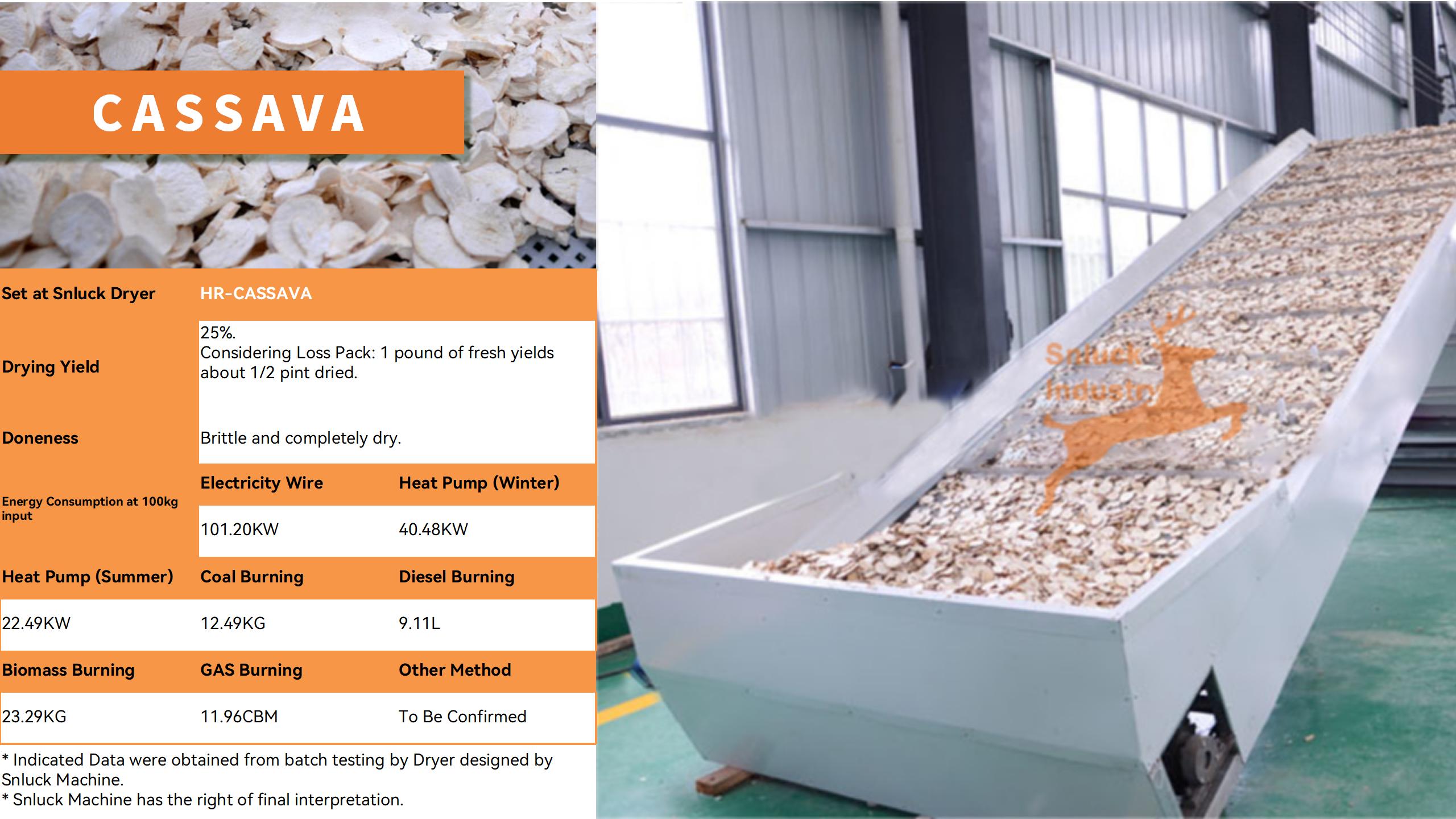

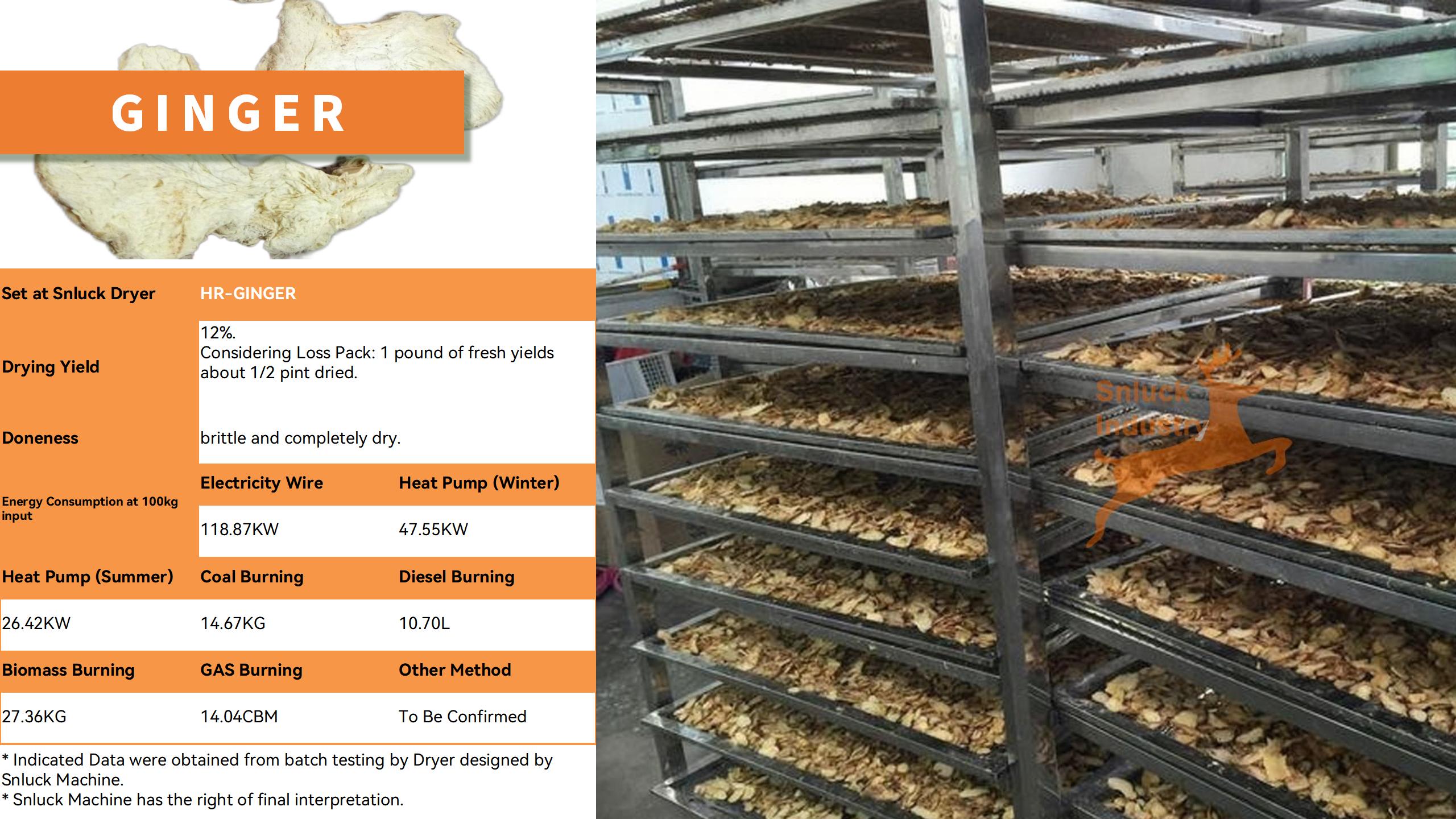

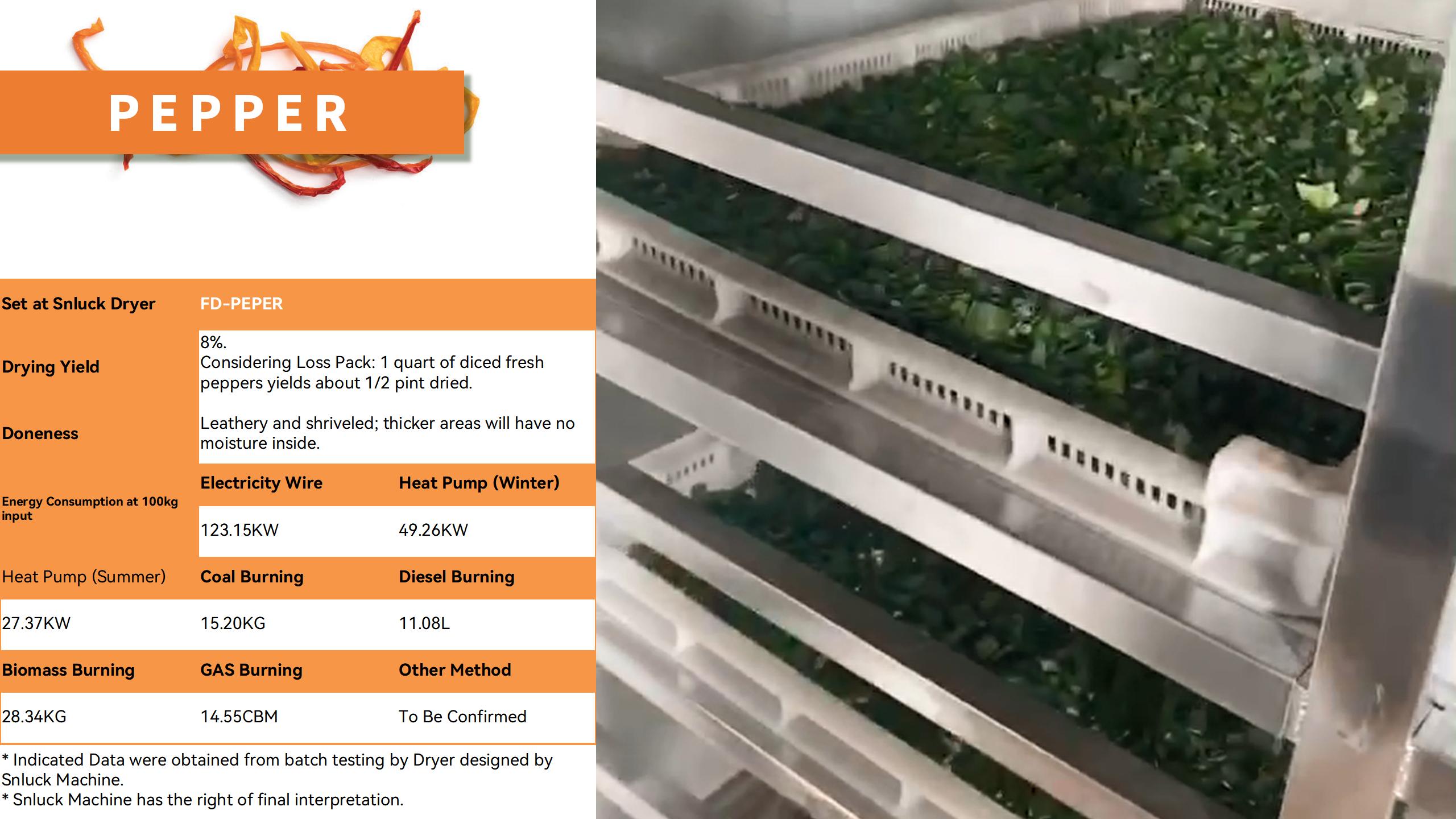

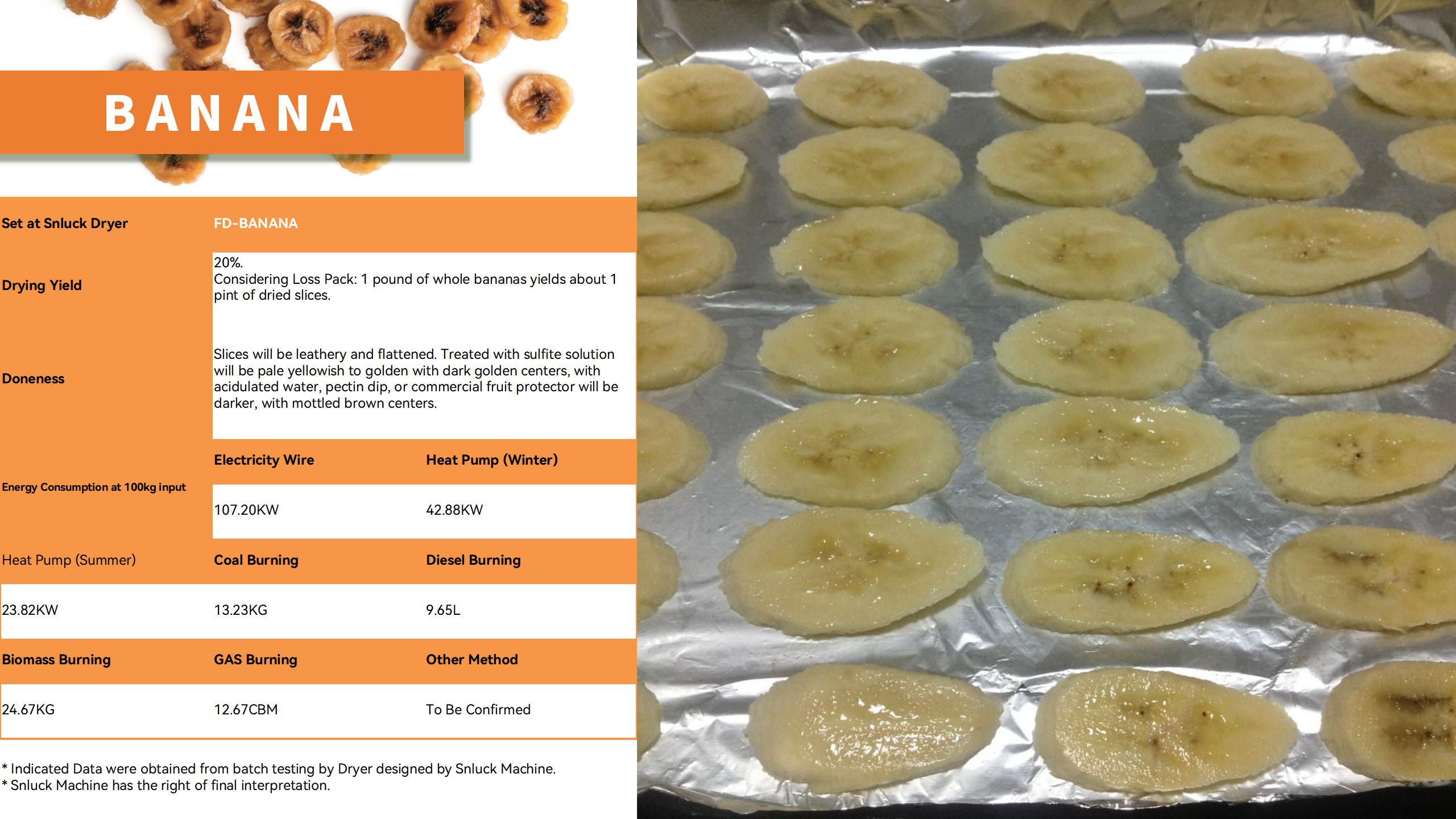

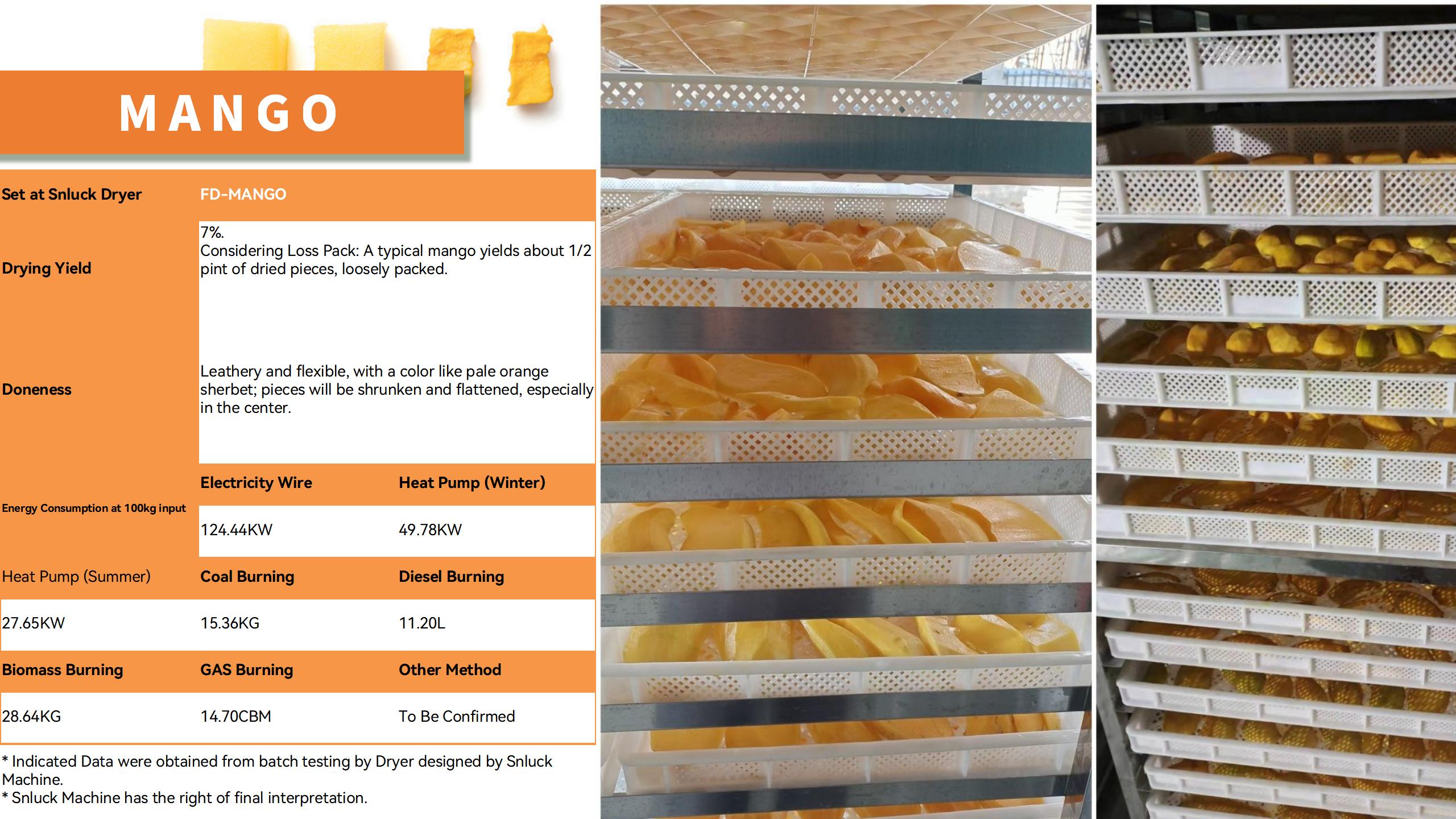

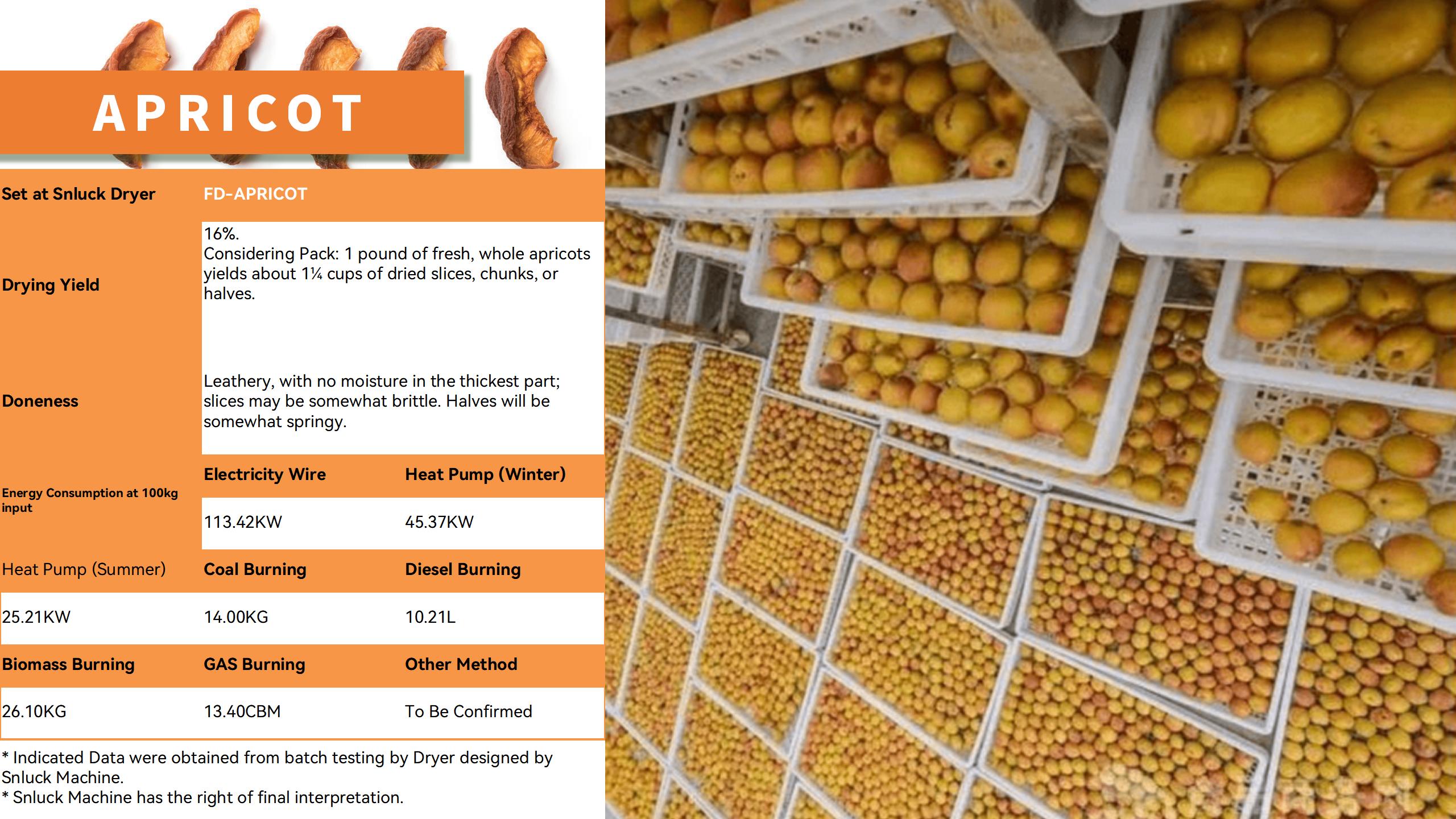

Various Type Materials Well-Drying –

Construct Reliable Dehydrator –

Cases

Snluck Study

Combines advanced technology and expert knowledge to deliver precise, high-quality drying results tailored to your specific goals.

-Data source by Snluck Industry Annual Report 2024